IoT Digital Twin in Home Appliances Industry—Optimizing Smart Vacuum Cleaner Manufacturing

Introduction

Smart vacuum cleaners have transformed home cleaning by combining robotics, AI, and connectivity to deliver efficient and autonomous cleaning solutions. Manufacturing these sophisticated devices requires precision, adaptability, and quality control. Integrating IoT Digital Twin in Home Appliances Industry technology in the manufacturing process enables real-time monitoring, predictive maintenance, and quality assurance, leading to improved production efficiency and product reliability.

This case study examines how IoT Digital Twin technology optimized the production of smart vacuum cleaner components and assembly, detailing the IoT process and benefits realized.

Challenges in Smart Vacuum Cleaner Manufacturing

- Complex assembly of mechanical, electronic, and sensor components.

- Ensuring consistent product quality amidst variability in parts.

- Managing supply chain synchronization for just-in-time manufacturing.

- Limited visibility into production line efficiency and equipment health.

Process of IoT in Smart Vacuum Cleaner Manufacturing

- Sensing (Data Collection)

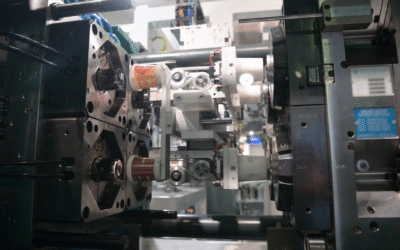

Sensors were embedded on key manufacturing stations including PCB assembly, motor calibration, brush installation, and final testing. IoT sensors collected data on temperature, humidity, vibration, assembly torque, and electrical parameters. This comprehensive data set formed the backbone of the IoT Digital Twin in Home Appliances Industry by accurately reflecting real-time factory conditions.

- Transmission (Data Transfer)

The sensor data was transmitted via secure industrial wireless networks to edge devices located near the production line. These edge devices acted as local aggregators, forwarding filtered data to cloud servers to support the digital twin’s virtual environment.

- Data Processing (Edge or Cloud Computing)

Initial data cleansing and preprocessing were performed at the edge to ensure rapid anomaly detection. More sophisticated analytics, including AI-driven diagnostics and simulations, ran on cloud platforms, enabling deep insights into manufacturing performance and predictive maintenance of robotic assembly arms.

- Data Storage

All processed data was stored securely in scalable cloud databases, allowing historical performance analysis, model retraining, and long-term quality trend tracking, essential for continuous improvement within the IoT Digital Twin in Home Appliances Industry framework.

- Data Analysis (AI/ML Integration)

Machine learning algorithms analyzed assembly torque variations, motor calibration parameters, and sensor output consistency to identify potential defects early. AI models also predicted equipment wear and pinpointed bottlenecks, facilitating data-driven improvements in production scheduling and quality control.

- Decision Making / Action Execution

Real-time alerts and control commands were generated based on AI insights. For example, if the torque applied during brush assembly deviated beyond thresholds, automated adjustments were made or the item flagged for inspection. This closed-loop feedback ensured high build quality and minimized rework.

- User Interface

Operators and supervisors accessed real-time dashboards showing equipment status, production metrics, and quality alerts. The user-friendly interface enabled quick decision-making and streamlined communication between teams, improving overall operational efficiency.

- Digital Twin Interface (Remote Monitoring & Control)

The digital twin provided a virtual replica of the entire smart vacuum cleaner assembly line, allowing remote monitoring, simulation of process changes, and predictive maintenance planning. Engineers used the digital twin to optimize line balancing and troubleshoot issues without halting production.

Results and Impact

Implementation of the IoT Digital Twin in Home Appliances Industry solution in smart vacuum cleaner manufacturing delivered measurable improvements:

| Metric | Before Implementation | After Implementation |

| Assembly Line Downtime (hours/month) | 12 | 4 |

| Product Defect Rate (%) | 3.8 | 1.0 |

| Average Calibration Time (mins) | 15 | 8 |

| First-Pass Yield (%) | 88 | 96 |

| Quality Inspection Time (mins) | 5 | 2 |

- Reduced downtime through predictive maintenance of robotic arms and assembly stations.

- Improved product quality with real-time detection of assembly deviations.

- Faster calibration and testing phases, shortening overall production cycle.

- Enhanced operational visibility and data-driven decision-making.

Benefits of IoT Digital Twin in Home Appliances Industry in Smart Vacuum Cleaner Manufacturing

- Enhanced Equipment Reliability and Reduced Downtime

Continuous condition monitoring and predictive analytics reduce unplanned stoppages, keeping the assembly line running smoothly. - Superior Product Quality and Consistency

Real-time monitoring of assembly parameters and testing results ensures defects are detected early, improving overall product reliability. - Cost Optimization

By preventing rework and optimizing tool usage, manufacturers lower operational costs and improve yield rates. - Process Innovation and Agility

The digital twin allows engineers to virtually test new manufacturing methods or product variants, accelerating innovation cycles. - Improved Workforce Efficiency

Intuitive dashboards and automated alerts reduce human errors and improve coordination among production teams. - Foundation for Smart Factory Evolution

The solution supports seamless integration with other smart manufacturing technologies, facilitating future scalability.

Conclusion

The use of IoT Digital Twin in Home Appliances Industry in the manufacturing of smart vacuum cleaners has proven to be a game-changer. By integrating real-time data collection, AI-driven analysis, and digital twin simulations, manufacturers achieved improved product quality, reduced downtime, and enhanced operational efficiency.

This case study highlights how adopting IoT digital twin technology can empower home appliance manufacturers to stay competitive in a rapidly evolving market, meeting consumer demands for smarter, more reliable products. For more content, visit EFFE Technology.