IoT DIGITAL TWIN

Control your real-world space in 3D with smart IoT and immersive AR/VR technology.

IoT Digital Twin Services

A Digital Twin powered by IoT (Internet of Things) is a virtual replica of a physical asset, system, or process that uses real-time data to simulate, analyze, and optimize performance. By integrating IoT sensors with digital modeling, Digital Twins offer continuous monitoring, predictive maintenance, and data-driven decision-making. In industries like manufacturing, energy, and healthcare, they help improve operational efficiency, reduce downtime, and enhance product innovation. The real-time data collected from IoT devices enables businesses to visualize system behaviors, predict future outcomes, and respond proactively to issues before they escalate. This powerful combination of physical and digital intelligence fosters smarter operations and strategic planning. As IoT technology evolves, Digital Twins are becoming more scalable, accessible, and integral to Industry 4.0 and smart city applications. Ultimately, IoT-based Digital Twins revolutionize how businesses manage assets, streamline operations, and deliver value in a data-driven world.

Our Services

Our technology incorporation has brought a revolution in the design firms and branding with full-service marketing.

Smart System Monitoring in Real Time

EFFE’s Smart System Monitoring leverages IoT Digital Twins to mirror real-world operations in virtual environments. Monitor performance, detect anomalies, and respond instantly using real-time sensor data. Ideal for manufacturing, healthcare, and logistics, our smart apps improve safety, efficiency, and scalability with full operational visibility and proactive control.

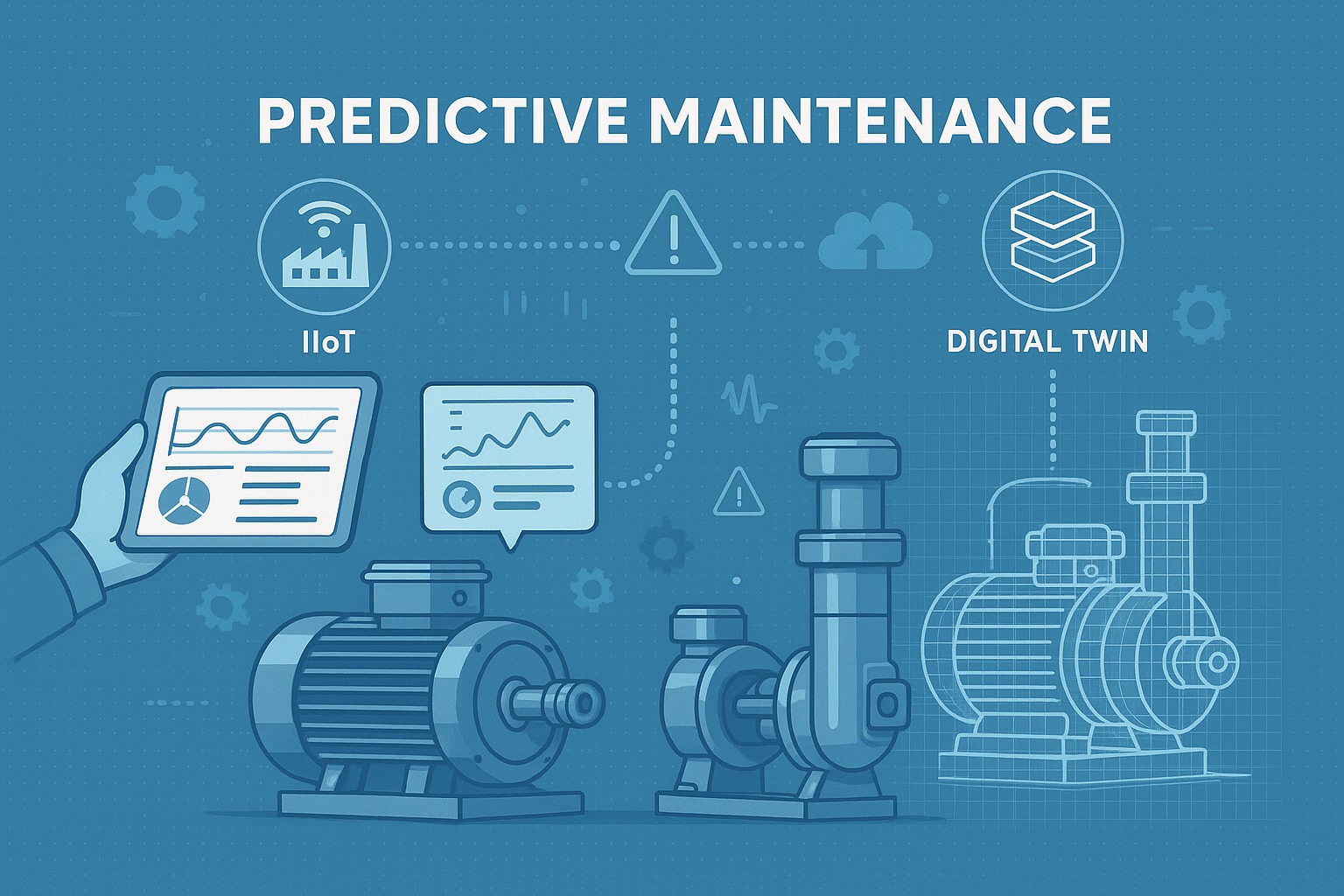

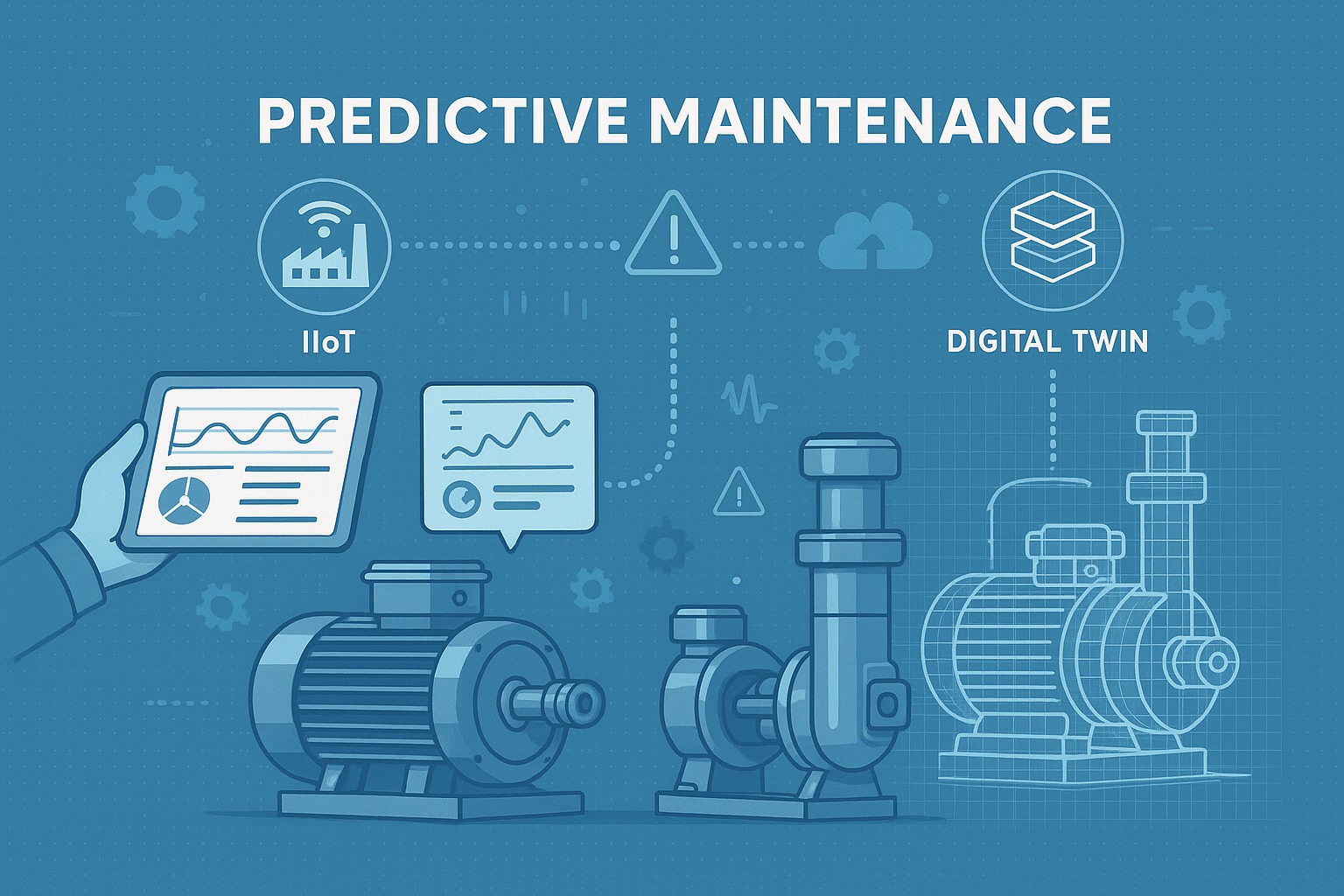

Predictive Maintenance Using Digital Twin

EFFE’s Predictive Maintenance solution uses Digital Twin Technology to foresee equipment failures before they happen. Real-time IoT data and AI models track wear, detect irregularities, and suggest maintenance actions. This proactive approach minimizes downtime, extends asset life, and lowers costs—perfect for industries reliant on continuous operations and infrastructure.

Predictive Maintenance Using Digital Twin

EFFE’s Predictive Maintenance solution uses Digital Twin Technology to foresee equipment failures before they happen. Real-time IoT data and AI models track wear, detect irregularities, and suggest maintenance actions. This proactive approach minimizes downtime, extends asset life, and lowers costs—perfect for industries reliant on continuous operations and infrastructure.

Process Optimization with Live Insights

EFFE’s Process Optimization platform transforms IoT data into real-time insights using Digital Twin environments. Visualize and refine workflows across manufacturing, healthcare, or logistics. Our system identifies inefficiencies, simulates improvements, and provides AI-driven recommendations for better speed, quality, and cost-efficiency—enabling continuous improvement and smarter business decisions at every level.

Efficiency Enhancement through IoT Twins

EFFE’s IoT Twin solutions mirror your operations in real time, enabling predictive insights and performance boosts. With live sensor data, the Digital Twin suggests energy savings, load balancing, and workforce efficiency improvements. From smart factories to healthcare, we deliver adaptive, data-driven applications to maximize productivity and minimize operational waste.

Efficiency Enhancement through IoT Twins

EFFE’s IoT Twin solutions mirror your operations in real time, enabling predictive insights and performance boosts. With live sensor data, the Digital Twin suggests energy savings, load balancing, and workforce efficiency improvements. From smart factories to healthcare, we deliver adaptive, data-driven applications to maximize productivity and minimize operational waste.

Our Process

Our team uses the simplified development approach to create a mobile application that perfectly matches your business requirements.

Discovery & Consultation

Discussing your vision and identifying how IoT-Digital Twin can benefit your business.

Data Collection & IoT Integration

Creating detailed IoT concepts that align with your goals and industry standards.

Digital Twin Model Creation

Building interactive prototypes that demonstrate the Digital Twin experience.

Analytics & Optimization

Implementation & Integration

Seamless digital twin integration ensures compatibility and continuity.

Reporting & Insights Delivery

Actionable insights, reports, dashboards empower continuous improvement..

Explore Our Portfolio

EFFE Technology offers custom applications and software development services that perfectly suit your business needs. We deliver software solutions with new capabilities that respond to the current trend of this technological world.

Industries We Serve

Food

Construction

Healthcare

Electronic

Automotive

Textile

Iron

Logistics

Solar

Plastic

Our Case Studies

Explore in-depth analyses of our innovative projects, highlighting the challenges faced, strategies implemented, and measurable outcomes achieved, showcasing our expertise and commitment to delivering impactful methods.