Overview

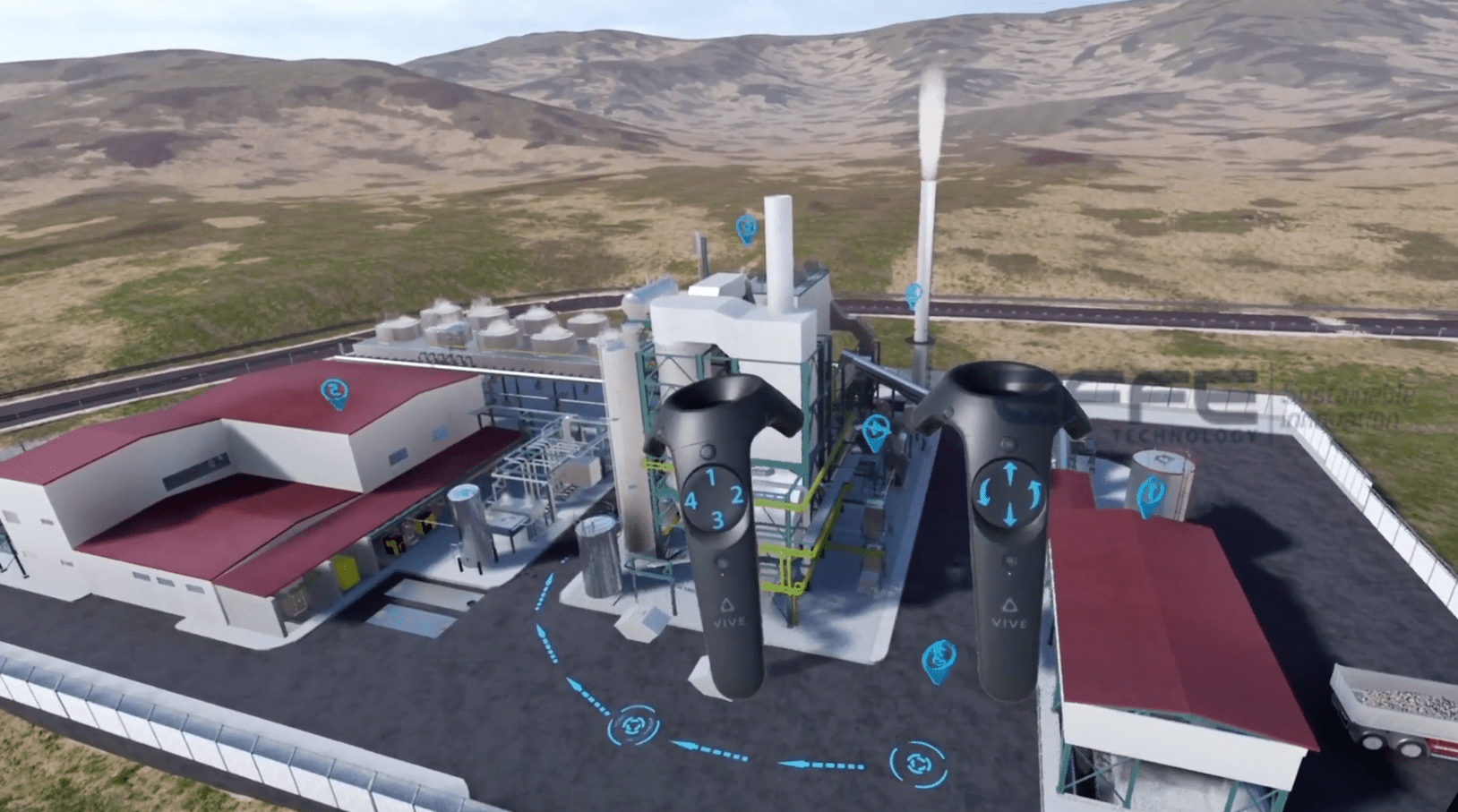

This project delivers a high-impact VR plant tour experience for a large food manufacturing facility using Digital Twin and immersive virtual reality factory technology. The solution enables customers, partners, auditors, and trainees to explore the factory remotely through a virtual company tour and virtual industrial visit, making complex manufacturing processes easy to understand without physical site visits.

Project Requirement

The client, a leading food manufacturing company, wanted to modernize how they showcase their production facility to customers, regulatory bodies, new employees, and global stakeholders. Physical factory visits were expensive, time-consuming, and restricted due to safety, hygiene, and production schedules.

They needed a scalable VR plant tour solution that could:

- Replace most physical factory visits with a virtual industrial visit

- Present the complete facility as an immersive virtual reality factory

- Create a guided virtual company tour for sales, audits, and training

The core objective was to build a future-ready VR plant tour that works as a single digital asset for marketing, training, and enterprise communication.

Project Planning

The planning phase began with stakeholder workshops involving production, quality, engineering, and IT teams. The goal was to map the factory layout, identify key storytelling points, and define the ideal user journey for the VR plant tour.

The strategy included:

- Structuring the plant into logical zones inside the virtual reality factory

- Designing a guided virtual company tour and a free-explore mode

- Mapping the entire process flow for an accurate virtual industrial visit experience

- Creating a modular system so the VR plant tour could be reused for different audiences

Project Process & Execution

1. Factory Study & Data Collection : We collected CAD drawings, layout plans, process flow documents, and visual references. This ensured the virtual reality factory accurately reflected the real facility and that the VR plant tour would be technically correct.

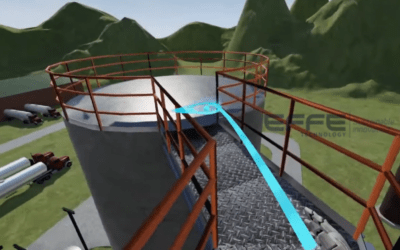

2. 3D Plant & Digital Twin Development : A complete 3D replica of the factory was created, forming the foundation of the virtual industrial visit. Machines, conveyors, utilities, and workstations were modeled to scale and connected to Digital Twin logic wherever required.

3. Experience Design & Storytelling : The VR plant tour was designed as a guided virtual company tour with interactive hotspots, process explanations, and animated workflows. Users can also explore freely, making the virtual reality factory both informative and engaging.

4. Interaction & Information Layers : Users can click on machines to learn their function, understand quality checks, and visualize material flow. This turns the VR plant tour into a practical learning and sales tool, not just a visual demo.

5. Optimization & Deployment : The experience was optimized for VR headsets, web browsers, and desktops, enabling the virtual industrial visit to be used in sales meetings, exhibitions, training rooms, and management presentations.

Challenges

- Complex Manufacturing Environment

Representing a live factory inside a virtual reality factory without oversimplifying processes was challenging. - Performance vs Visual Quality

Maintaining smooth performance in the VR plant tour while keeping high visual fidelity required heavy optimization. - Multi-Stakeholder Expectations

Sales, training, and operations teams all wanted different outcomes from the virtual company tour. - Accuracy & Compliance

Ensuring the virtual industrial visit stayed aligned with real-world operations and safety standards was critical.

Key Learnings

- A well-designed VR plant tour can replace 80–90% of physical factory visits.

- Storytelling is as important as realism in a virtual company tour.

- A virtual reality factory becomes a long-term business asset, not just a marketing tool.

- Virtual industrial visit platforms significantly improve training speed and stakeholder understanding.

- Modular design ensures the same VR plant tour serves sales, training, and audits.

Client Deliverables

- Complete VR plant tour platform

- Immersive virtual reality factory environment

- Guided virtual company tour and free-roam mode

- Digital Twin–based virtual industrial visit visualization

Conclusion

This VR plant tour project successfully transformed a physical manufacturing facility into an immersive digital experience. The virtual reality factory now enables the client to present their operations globally, train employees faster, reduce travel costs, and improve transparency.