Project Overview

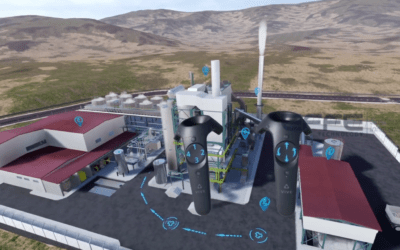

As trade shows grew costly and complex, a manufacturing brand across Industrial Automation, Pharma, and FMCG adopted a VR Manufacturing Walkthrough solution. This immersive VR Factory Simulation replaced physical booths, enabling secure Factory VR Visualization, higher engagement, and better-qualified leads at global exhibitions through an interactive Virtual Production Tour.

Business Requirement

The client needed a cost-effective, high-impact alternative to conventional exhibition setups. Their key requirements included:

- Reduced Exhibition Costs & Footprint : The VR Manufacturing Walkthrough replaced bulky physical booths with a compact, portable setup—cutting logistics, space, and setup costs while still delivering a high-impact Factory VR Visualization experience at trade shows.

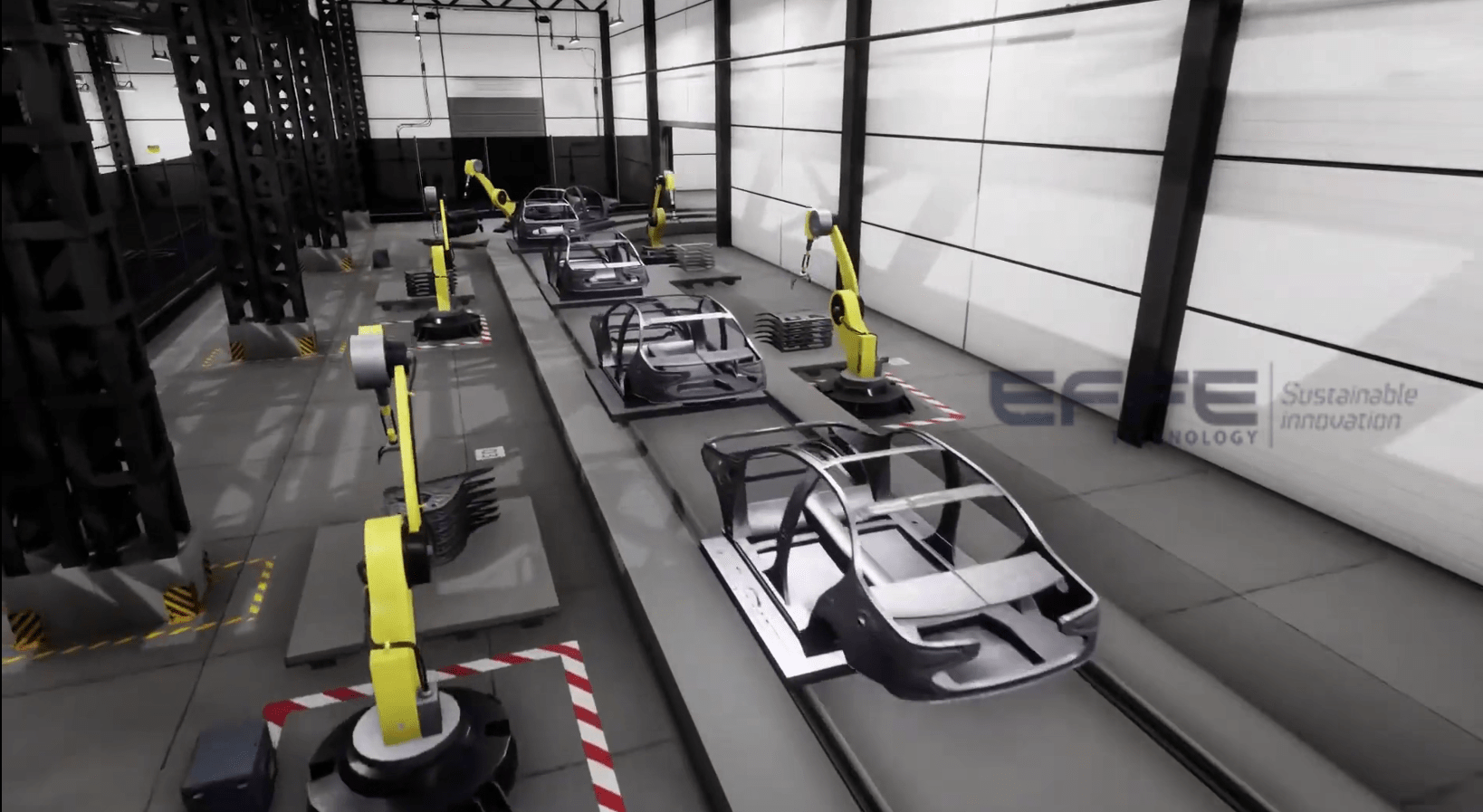

- Showcasing the Complete Production Process : The VR Production Line Tour allowed prospects to explore end-to-end operations without stopping live production, ensuring zero downtime while still demonstrating scale, precision, and operational excellence through a VR Factory Simulation.

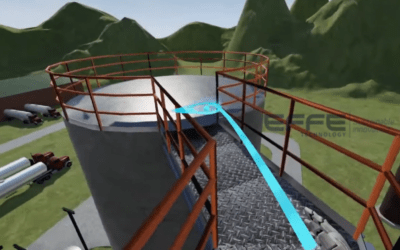

- Secure & Compliant Access to Restricted Areas : Through a carefully designed Virtual Production Tour, the client enabled secure visibility into restricted zones—maintaining compliance with Pharma and FMCG regulations while building buyer trust and confidence using controlled Factory VR Visualization.

- Single VR Asset for Global Sales & Exhibitions : One scalable VR Manufacturing Walkthrough supported multiple touchpoints—from global exhibitions to distributor meets and client presentations—ensuring consistent messaging and faster deployment across markets.

Project Planning & Strategy

- Process & Environment Study : Mapped factory processes and risk zones to maximize the impact of the VR Manufacturing Walkthrough while ensuring compliance and operational accuracy.

- Content & Experience Structuring : Created a modular VR Factory Simulation journey replacing linear video, showcasing the VR Production Line Tour, safety standards, and key brand differentiators.

- Technology & Platform Planning : The Factory VR Visualization solution was built for HMDs, kiosks, and laptops, ensuring smooth performance and quick setup at trade shows.

- Compliance, Security & Accuracy : Ensured the Virtual Production Tour met Pharma and FMCG standards through multi-team approvals and secure content validation.

Challenges & Key Learnings

1. Limited Access to Detailed Manufacturing Data

Challenge: Restricted access to certain shop-floor areas and incomplete documentation slowed early development.

Learning: A modular VR Manufacturing Walkthrough approach allowed parallel development while approvals continued—reducing delays.

2. Balancing Realism with Trade-Show Performance

Challenge: Highly detailed VR Factory Simulation risked lag on portable hardware.

Learning: Optimized Factory VR Visualization ensured smooth demos without sacrificing accuracy—critical for live exhibitions.

3. Showcasing Compliance Without Revealing IP

Challenge: Demonstrating quality systems and automation without exposing sensitive data.

Learning: Guided storytelling within the Virtual Production Tour conveyed capability and compliance effectively—especially important in regulated industries.

Client Deliverables

The client received a complete, future-ready VR Manufacturing Walkthrough solution designed for long-term value:

1. Immersive VR Manufacturing Walkthrough

- 30-minute guided Virtual Production Tour

- End-to-end Factory VR Visualization of production lines, automation, and quality checkpoints

- Optimized for trade shows, sales meetings, and internal presentations

2. Interactive Manufacturing Modules

- VR Production Line Tour experiences

- PPE usage and safety compliance

- Emergency response scenarios

- Fault identification and rectification

3. Trade Show–Ready Deployment

- Quick setup and teardown

- Minimal physical space compared to traditional booths

- Optimized VR Factory Simulation for portable hardware

Conclusion

By replacing physical booths with a VR Manufacturing Walkthrough, the client achieved higher engagement, improved lead quality, and a modern brand perception—while significantly reducing exhibition costs. The Virtual Production Tour, powered by Factory VR Visualization and VR Production Line Tour experiences, became a powerful trust-building tool, helping prospects experience the factory before ever stepping on-site.