Overview

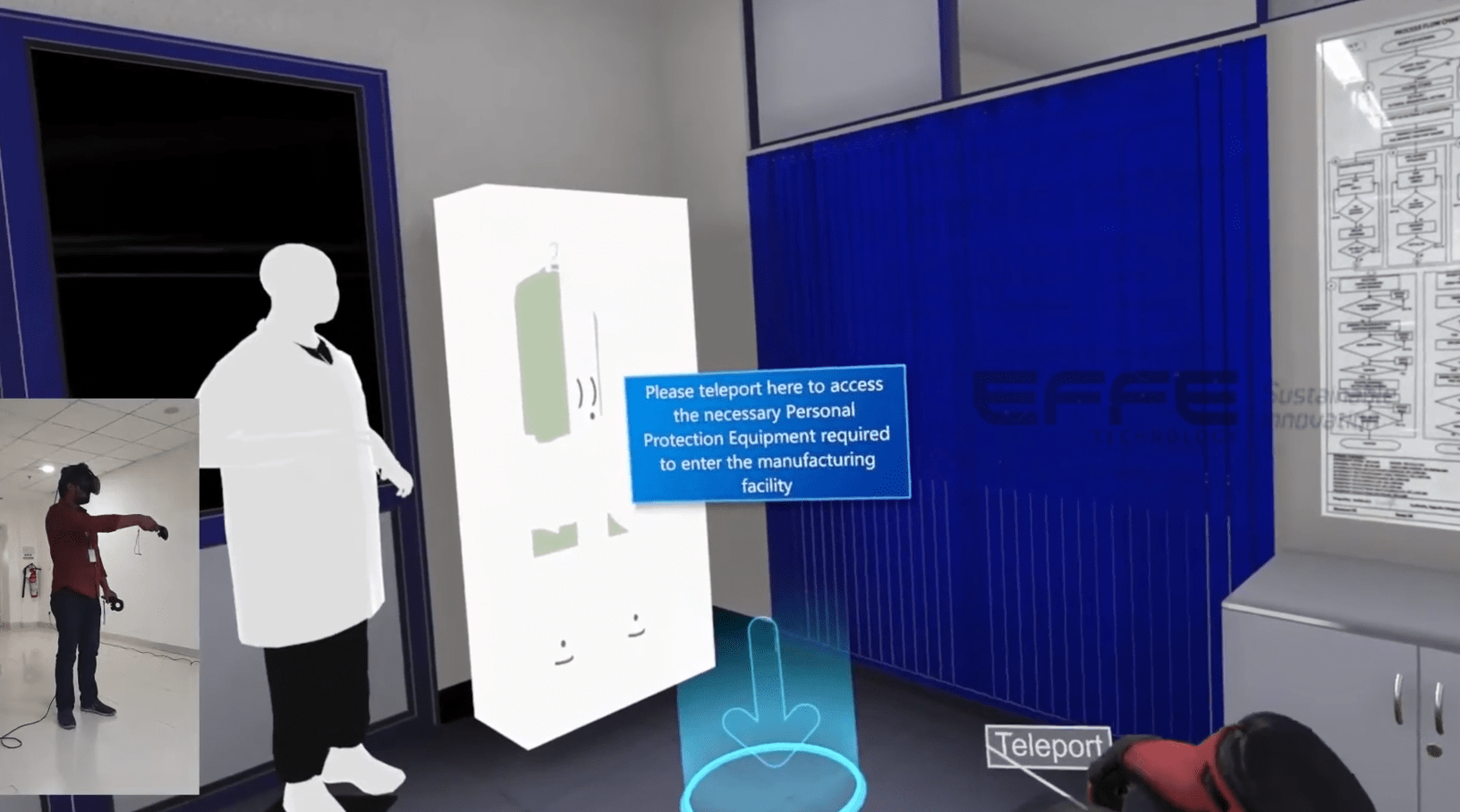

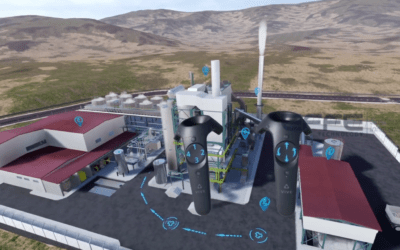

This case study explores a VR Industrial Tourism initiative that transformed traditional plant visits into immersive, scalable experiences, leveraging VR Industrial plant tour, mechanical procedure VR, and enriched manufacturing excursion in India offerings for global stakeholders and clients.

Project Requirement

A leading manufacturing company in India sought to modernize its physical tour process and create a virtual platform that could replicate the in-plant experience. The aim was to:

- Develop a VR Industrial Tourism module that showcased core facilities.

- Enable a VR Industrial plant tour for remote clients, investors, and students.

- Highlight detailed mechanical procedure VR sequences for complex processes.

- Strengthen VR Industrial tourism in companies as a scalable business tool.

This project had to reflect the technical level of the company’s operations while ensuring ease of use for non-technical audiences – from executives to academic visitors interested in manufacturing excursion in India.

Project Planning

Initial planning spanned four weeks and included the following core phases:

- Discovery & Research

- Identifying key areas to be included in the VR Industrial plant tour.

- Documentation of mechanical systems for mechanical procedure VR

- Concept & Storyboarding

- Script development for the VR narrative.

- Prioritizing experiences: heavy machinery operations, safety walkthroughs, and technical demonstrations.

- Tech Stack Selection

- Choosing appropriate engines (Unity/Unreal) and compatible VR hardware.

- Integration of 360° video capture for realistic VR Industrial Tourism.

- Timeline & Deliverables

- 12-week development window with iterative milestones.

- Parallel tracks for 3D modeling, VR coding, and QA testing.

Project Process & Execution

The execution phase spanned 12 weeks and was divided into three major sprints:

Environment Capture & Modeling

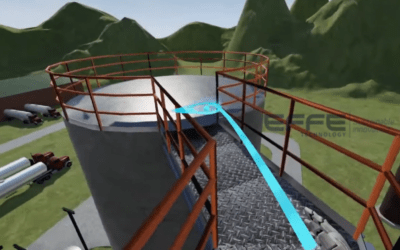

- Conducted in-plant 360° capture sessions across production units.

- Gathered CAD files and schematics to build accurate VR spaces.

- Focused on areas with the most educational value for manufacturing excursion in India

Integration of Experiences

- Developed interactive hotspots in the VR industrial plant tour, explaining machinery function and safety.

- Built mechanical procedure VR modules that walked users through step-by-step assembly and production sequences.

- Embedded narration, subtitles, and interactive prompts for multi-language support.

- Enabled guided and self-guided modes for flexibility.

Testing & Optimization

- Conducted usability tests with internal teams and external stakeholders.

- Iterated based on feedback to improve navigation and comfort.

- Implemented accessibility features to ensure broader adoption.

Challenges

While the project delivered high impact, it faced several challenges:

- Data Accuracy vs Performance

- Detailed CAD models slowed performance in early builds.

- Solution: Simplified render layers while preserving visual fidelity.

- Communicating Technical Processes

- Converting complex mechanical operations into intuitive mechanical procedure VR walk-throughs wasn’t straightforward.

- Solution: Added guided voiceovers and visual cues for clarity.

- User Comfort & Accessibility

- Early tests reported motion discomfort.

- Solution: Adjusted locomotion approach and optimized framerate.

- Language Diversity

- India’s linguistic diversity required multi-language support.

- Solution: Created subtitle and narration packs in key languages.

Despite these challenges, the team ensured that VR Industrial Tourism remained intuitive, informative, and true to the real plant experience.

Key Learnings

From this engagement, we derived the following insights:

- Empathy-led Design Matters: Technical environments like factories need simplified orientation layers for external visitors.

- Iterative Feedback Cycles Reduce Risks: Early VR testing prevented usability pitfalls later.

- Localization Boosts Adoption: Multi-language narration increases reach across domestic and international audiences.

- Scalable Architecture is Key: Designing the VR framework to support future modules (e.g., new plants or educational programs) ensures longevity.

This case also highlighted how VR Industrial Tourism could serve multiple business functions — from sales and marketing to training and compliance — especially in ecosystems prioritizing digital transformation.

Client Deliverables

The final deliverables packaged for the client included:

- Fully functional VR Industrial Tourism platform

- Walkthrough of major units via VR Industrial plant tour

- Interactive mechanical procedure VR modules

- Deployment Ready Files

- Compatible across major VR headsets (Quest, HTC Vive, etc.)

- Web-integrated 360° experiences for non-VR users

- Admin Dashboard

- Usage analytics to track engagement

- Content update interface for future expansions

- Training & Documentation

- Guides for internal teams to manage the VR experience

- Launch Plan & Support

- 2 weeks of post-deployment support

- Onsite demo sessions for key partners

Conclusion

The VR Industrial Tourism project successfully transformed traditional industrial tours, enabling immersive VR Industrial plant tour experiences that deepened stakeholder engagement. The solution also positioned the client as an innovator in VR Industrial tourism in companies, and as a benchmark for manufacturing excursion in India through VR.