Revolutionizing VR in Wind Industry with Immersive Simulations and Walkthroughs

Project Planning, Strategy, and Our Process

Requirement Analysis

EFFE Technology conducted a comprehensive analysis of the client’s wind turbine operations, identifying inefficiencies in training, maintenance, and data-driven decision-making. Collaborating with wind energy engineers and sustainability officers, we designed a VR in Wind Industry solution to simulate real-world turbine scenarios that boost operational understanding and technical skills.

Design and Development

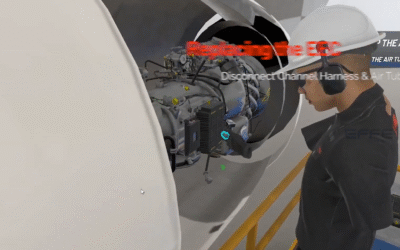

We developed an advanced VR in Wind Industry application focusing on immersive and interactive training experiences. The simulation system included:

- Virtual Wind Turbine Walkthroughs: 360-degree tours of turbine interiors and exteriors for deep visual understanding.

- Maintenance Training Modules: Interactive simulations for common repairs, inspections, and emergency procedures.

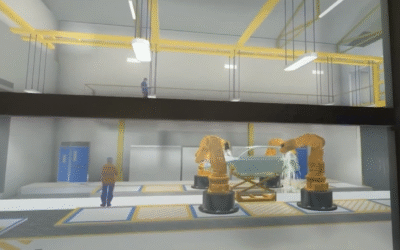

- Realistic Environment Rendering: Weather dynamics, turbine heights, and terrain-based walkthroughs mimicking real-world turbine settings.

- Live Performance Simulations: Real-time performance monitoring features within the VR space to understand operational behavior.

Customization and Scalability

The platform was designed with scalability in mind, allowing for the addition of different turbine models, updated procedures, multilingual training support, and new learning modules, making VR in Wind Industry adaptable to global clients and technologies.

Testing and Feedback Loop

A pilot test was conducted with turbine technicians and engineers. Their feedback helped enhance the precision of equipment modeling, interaction fluidity, and safety procedure accuracy within the VR in Wind Industry simulation, leading to a better user experience and learning retention.

Deployment and Training

We deployed the solution across VR headsets, tablets, and desktop platforms, offering immersive access to trainees both on-site and remotely. Hands-on training sessions were provided to ensure that operational teams could fully leverage the VR in Wind Industry tools.

Deliverables and Client Benefits

Deliverables

- Custom-built VR in Wind Industry simulation application with realistic turbine walkthroughs.

- Interactive training modules with repair, inspection, and emergency protocols.

- Backend analytics dashboard for monitoring trainee progress and turbine efficiency.

- Multiplatform deployment for ease of access across VR devices and desktop.

- Scalable design for future upgrades and global deployment.

Client Benefits

- Improved Operational Training: Technicians could explore and practice in a virtual setting, leading to faster skill development.

- Reduced Downtime: Preventive training and scenario practice led to fewer real-world errors and faster response times.

- Cost Efficiency: Eliminated the need for expensive on-site training sessions and minimized physical wear on turbine components.

- Eco-Friendly Development: The VR in Wind Industry application promoted renewable energy understanding and sustainable operational decisions.

- Enhanced Decision-Making: Real-time data tracking and performance simulation offered actionable insights for management.

Conclusion

The VR in Wind Industry solution by EFFE Technology redefined how wind energy companies train their teams, maintain assets, and optimize operations. Through immersive walkthroughs and realistic turbine simulations, this project not only reduced training costs and downtime but also strengthened eco-friendly practices and decision-making in renewable energy. As VR in Wind Industry continues to evolve, solutions like these are vital to achieving sustainability and performance at scale. Visit our partner site.