Project Title:

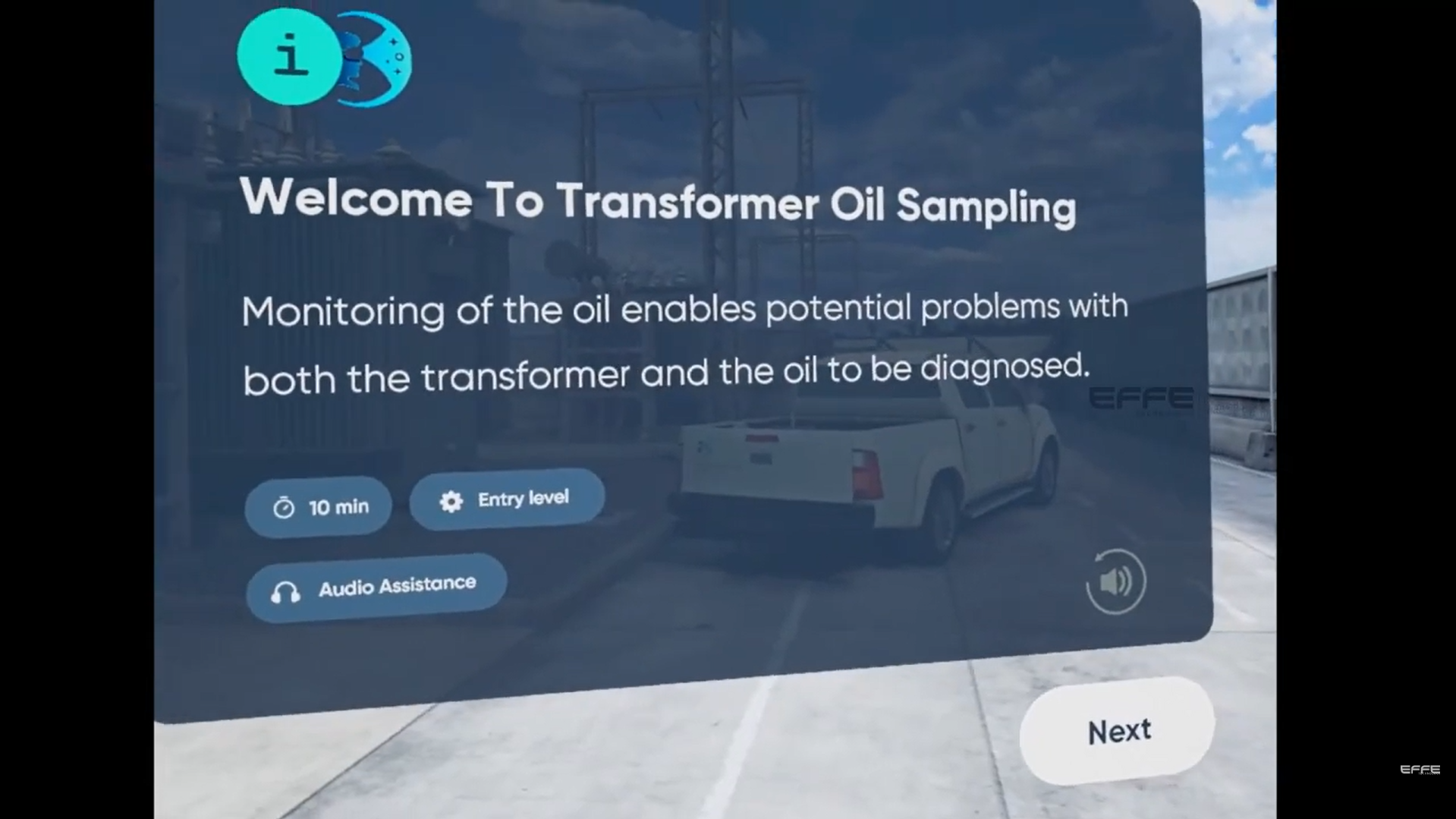

Immersive Transformer Oil Sampling & Analysis Training Using VR

Short Description:

Our client, a leading oil manufacturing and power maintenance company, wanted a modern, safe, and efficient way to train employees in transformer oil sampling and insulating oil analysis. We developed a fully interactive VR training simulation that allows technicians to practice oil sampling, handling tools, and performing testing procedures in a controlled virtual environment. This project highlights the power of VR in oil industry training and VR in oil maintenance training for improving accuracy, safety, and productivity.

Project Requirement:

The client needed a training solution that would:

-

Train new and existing employees on correct transformer oil sampling procedures

-

Reduce errors during real-world maintenance

-

Provide risk-free practice for handling high-voltage equipment

-

Improve understanding of oil degradation, contamination, and diagnostic testing

-

Standardize training across multiple plant locations

-

Track employee performance and skill progress

Since Transformer oil sampling and its further analysis directly affects the safety, life, and performance of power equipment, the client required an immersive system that replicates real workflows without operational downtime.

Project Planning:

We followed a structured planning process:

1. Requirement Analysis

We studied the client’s current oil sampling procedure, testing standards, safety protocols, and industry manuals to create a realistic simulation framework.

2. Script & Scenario Development

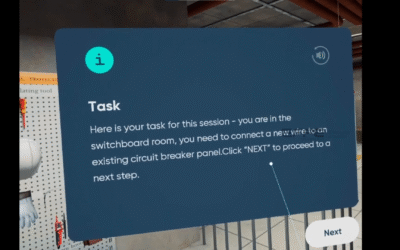

We developed a step-by-step scenario covering:

-

Pre-checks

-

PPE selection

-

Tool identification

-

Sampling valve operation

-

Oil collection

-

Sealing & labeling bottles

-

Transport & lab entry

-

Oil analysis steps

All training stages were approved by the client’s subject-matter experts.

3. 3D Asset & Environment Design

We created high-quality 3D models of:

-

Transformers

-

Sampling ports

-

Oil containers

-

Testing equipment

-

Safety tools

-

Plant environment

These assets ensured full realism and industry-standard accuracy.

4. Interaction & Programming

Using interactive VR controls, users can:

-

Operate sampling valves

-

Use tools correctly

-

Collect oil samples

-

Perform contamination check

-

Simulate BDV (Breakdown Voltage) testing

-

Complete full analysis workflow

Project Process & Execution:

Step-by-step Approach

-

Prototype Development – A basic VR module showing transformer layout and sampling points

-

Client Review & Validation – Ensured alignment with real procedures

-

Full Simulation Build – Added animations, interactions, voice guidance, and tutorials

-

Testing & Refinement – Performed QA tests, safety checks, and user testing

-

Final Deployment – Delivered VR modules compatible with both standalone and PC-VR systems

Training Features

-

Guided Mode: Helps beginners with step-by-step instructions

-

Assessment Mode: Tests technician skills without hints

-

Realistic Errors & Feedback: Warns users about incorrect sampling methods

-

Performance Analytics: Tracks completion time, accuracy, and errors

This makes the solution a benchmark example of VR in oil industry training, improving both learning speed and retention.

Challenges & Learning:

1. Replicating High-Voltage Environments

Ensuring accurate simulation of transformer operational behavior required close collaboration with electrical engineers.

2. Precision in Sampling Workflow

We had to mimic every small detail—tool size, valve angle, sample bottle handling—to achieve high training realism.

3. Safety Protocol Integration

Embedding PPE rules, hazard detection, and emergency prompts tested our design adaptability.

4. Client-Side Observations

Our team visited the client’s site to study real transformers, sampling pits, and oil testing labs. This field research strengthened the accuracy of our VR module.

Client Deliverables:

-

Full VR training module for transformer oil sampling

-

Interactive VR scenario for oil testing and analysis

-

High-quality 3D environment of the transformer yard

-

Guided & assessment training modes

-

User performance dashboard

-

Documentation & training manual

-

Deployment suppo