Empowering Workforce Skills through VR in Manufacturing Training

Project Planning, Strategy, and Our Process

Requirement Analysis

EFFE Technology initiated the project by conducting a thorough analysis of the client’s training challenges in a high-speed manufacturing environment. The client needed a cost-effective, risk-free, and scalable way to train workers on machinery, safety procedures, and production workflows. This led to our immersive solution using VR in manufacturing for hands-on, scenario-based learning.

Design and Development

We built a customized training simulation using VR in manufacturing principles to enhance productivity and safety. Key features included:

-

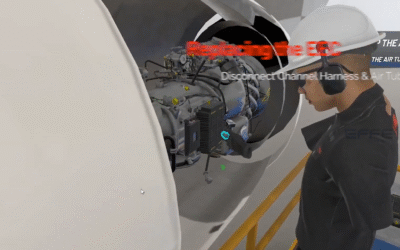

3D Machine Operation Training: Interactive tutorials simulating actual machinery usage and functions.

-

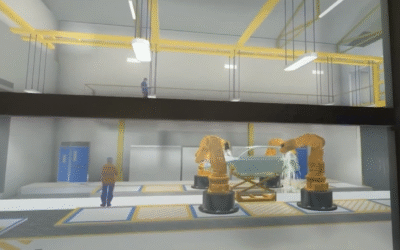

Process Simulation: Virtual walkthroughs of production lines, demonstrating each task with precision and sequence.

-

Safety Protocol Training: Immersive hazard identification and response simulations to reduce workplace accidents.

-

Interactive Skill Challenges: Gamified modules to assess and improve worker retention and task accuracy.

Customization and Scalability

Our VR in manufacturing system was designed to support multiple job roles, departments, and production lines. It enabled easy content updates to accommodate changes in machinery, compliance regulations, and process innovations.

Testing and Feedback Loop

We ran a pilot program within the client’s training department, allowing real employees to test the system. Their feedback helped optimize UI elements, simulation accuracy, and onboarding experience. This ensured the VR in manufacturing platform was intuitive and aligned with real-world tasks.

Deployment and Training

The solution was deployed using standalone VR headsets across training rooms and workshops. EFFE Technology offered detailed user guides and conducted train-the-trainer sessions to ensure the seamless integration of VR in manufacturing within the client’s existing workflow.

Deliverables and Client Benefits

Deliverables

-

Fully interactive VR in manufacturing simulation system

-

Role-specific modules for equipment use, safety, and assembly

-

Built-in performance tracking and feedback system

-

Multi-language support and training analytics dashboard

-

Deployment-ready package compatible with all major VR hardware

Client Benefits

-

Faster Onboarding: New employees learned faster with immersive, repeatable simulations

-

Lower Training Costs: Reduced downtime, trainer hours, and material wastage

-

Enhanced Safety Compliance: Workers practiced risk-free in dangerous virtual scenarios

-

Increased Engagement: Gamified modules boosted learner interest and retention

-

Scalable Growth: The VR in manufacturing framework could easily expand across departments and sites