Project Title:

Virtual Reality for Industrial Training – Equipment Operation & Safety Compliance

Description:

EFFE Technology developed an immersive Virtual Reality for Industrial Training solution for a manufacturing company to train employees on machine operation, PPE usage, and workplace safety procedures. The VR training eliminates real-world risk, provides repeatable practice, and ensures consistent learning across workers. This industrial training with virtual reality enhances practical skill development, reduces onboarding time, and improves overall safety culture within the factory environment.

Project Requirement:

The client, a mid-size manufacturing company, needed a modern training solution that:

- Teaches workers how to operate specific shop-floor machinery accurately.

- Ensures proper use of Personal Protective Equipment (PPE) before entering the production area.

- Provides zero-risk training for emergency scenarios and hazard recognition.

- Reduces dependency on in-person shadowing and live equipment downtime.

- Offers measurable progress tracking and employee skill evaluation.

EFFE Technology was tasked with creating a VR-based system that addressed all these requirements while remaining scalable and future-ready.

Project Planning:

EFFE Technology followed a structured planning approach:

- Requirement Study & Knowledge Gathering

- Conducted site visits and SOP analysis.

- Collected visuals, workflow sequences, machine details, and safety rules.

- Training Content Framework

- Prioritized modules for machine operation, PPE compliance, and emergency protocols.

- Prepared instructional design strategy and storyboard layouts.

- VR Platform Strategy

- Selected a hardware-friendly solution using standalone VR headsets.

- Planned LMS integration for performance tracking and certification.

- Pilot Scheduling & Testing Plan

- Set up pilot training with a small employee group.

- Prepared review timelines and improvement checkpoints.

Project Process & Execution

EFFE Technology executed the project in multiple phases:

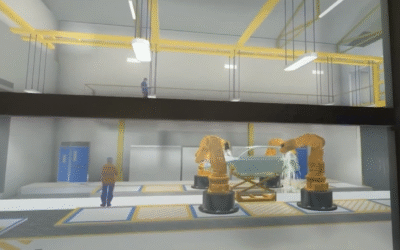

- 3D Environment & Asset Development

- Recreated factory floor, equipment, and workstations in realistic 3D.

- Built interactive equipment models to mimic real controls and movements.

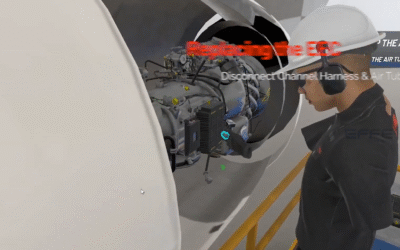

- Immersive VR Training Module Development

- Modules included:

- Correct PPE selection & verification

- Machine start-up & shutdown

- Material loading/unloading

- Lockout/Tagout procedures

- Emergency stop response

- Real-time guidance, feedback, and scoring systems were integrated.

- Modules included:

- Interactive Hazard Scenarios

- Simulated real workplace dangers such as:

- Hydraulic leaks

- Mechanical failure

- Pinch points

- Incorrect PPE use

- Employees practiced without exposure to real risk.

- Simulated real workplace dangers such as:

- Testing & refinement

- Conducted pilot rounds.

- Collected trainer and trainee feedback.

- Optimized UI, visual fidelity, and learning instructions.

- Deployment & Trainer Enablement

- Installed VR units in the client’s training space.

- Trained supervisors and admins on operations and data monitoring.

Challenges & Learning:

- Balancing realism and device performance:

Detailed equipment had to be optimized for smooth VR performance on cost-efficient headsets. - Change management resistance:

Traditional staff initially doubted VR training; live demos and pilot successes helped shift acceptance. - Continuous content updates:

Industrial processes evolve, so templates and update guidelines were given to maintain long-term relevance. - Capturing accurate SOP variations:

Internal procedures differed between shifts; models had to cover multiple user behaviors and scenarios.

Client Deliverables:

EFFE Technology provided:

- Fully interactive Virtual Reality for Industrial Training modules.

- Realistic factory-floor 3D environments and machine simulations.

- PPE compliance training and hazard simulation experiences.

- Assessment dashboards with user scoring, progress tracking, and performance reports.

- Installation & onboarding assistance for trainers and administrators.

- Editable content templates for future process updates.

- Integration with the client’s LMS for training records and certification.