IoT Digital Twin for Product Manufacturing—Enhancing Quality and Production Efficiency

Introduction

Manufacturing of engineering products like solar panels, wind turbines, and batteries involves highly complex processes where precision, consistency, and traceability are critical. These products are expected to perform in demanding environments for years, making manufacturing quality non-negotiable. The IoT Digital Twin for Product Manufacturing provides real-time insights into production parameters, equipment health, and product quality—allowing manufacturers to identify issues early, reduce waste, and optimize throughput.

This case study focuses on the production of solar PV panels, highlighting how IoT and digital twin technologies transformed manufacturing performance and quality assurance.

Challenges in Engineering Product Manufacturing

- High rejection rates due to micro-defects in solar cells or lamination errors.

- Inconsistent curing temperatures affecting panel durability.

- Limited real-time visibility into critical parameters like vacuum levels or coating uniformity.

- Manual data recording slowing down inspections and audits.

- Delays in identifying production issues, leading to wasted batches.

Process of IoT in Engineering Product Manufacturing

- Sensing (Data Collection)

IoT sensors were installed across laminators, soldering stations, vacuum pumps, and coating units to monitor temperature, humidity, cell alignment, current flow, pressure, and adhesive dispensing rate. This data powered the IoT Digital Twin for Product Manufacturing, creating a live mirror of the entire assembly line.

- Transmission (Data Transfer)

Sensor data was transmitted in real time via secure protocols to edge computing units and cloud platforms. This ensured seamless tracking of operations and equipment across multiple shifts.

- Data Processing (Edge or Cloud Computing)

Edge systems managed real-time alarms for out-of-range parameters (e.g., low vacuum or over-heating). Cloud AI models identified long-term trends, detected anomalies, and optimized machine settings for improved panel quality.

- Data Storage

Each panel’s production data was stored with a unique serial ID. Historical records included temperature profiles, visual inspections, energy throughput, and equipment parameters—supporting traceability and compliance audits.

- Data Analysis (AI/ML Integration)

Machine learning models identified defect patterns based on lamination pressure, glass thickness, and environmental data. AI optimized adhesive dispensing speed, cutting accuracy, and panel alignment.

- Decision Making / Action Execution

When thresholds were exceeded, systems auto-adjusted soldering temperatures or triggered a halt. Maintenance alerts were auto-generated for declining vacuum pump efficiency.

- User Interface

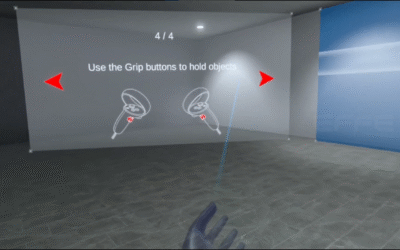

Operators accessed real-time dashboards showing production yield, machine health, and energy usage. Quality teams received alerts for potential micro-cracks or frame misalignments.

- Digital Twin Interface (Remote Monitoring & Control)

The IoT Digital Twin for Product Manufacturing replicated the entire panel production line digitally. Supervisors remotely monitored ongoing production, simulated process adjustments, and optimized settings before implementation.

Results and Impact

| Metric | Before Implementation | After Implementation |

| Production Defect Rate (%) | 4.5 | 1.2 |

| Panel Output Accuracy (Watt deviation) | ±5% | ±1.2% |

| Downtime per Month (hours) | 22 | 7 |

| Manual Inspection Time per Panel (mins) | 12 | 3 |

| Material Waste (kg/month) | 180 | 60 |

- 73% reduction in defect rate, driven by real-time quality control and predictive analytics.

- Panel output improved in consistency, with better energy yield predictability.

- Machine uptime significantly increased, with fewer failures and optimized maintenance schedules.

- Inspection process sped up, enabling faster deliveries with less labor.

- Substantial material savings, reducing both costs and environmental impact.

Benefits of IoT Digital Twin for Product Manufacturing

- Real-Time Quality Monitoring

Detects defects like micro-cracks, misalignments, or coating errors early in the process. - Predictive Maintenance

Reduces machine failures and extends the life of high-cost production assets. - Process Optimization

AI-driven adjustments fine-tune temperatures, pressures, and speeds for consistent output. - Reduced Waste and Rework

Identifies issues before batch completion, minimizing resource wastage. - Improved Traceability and Compliance

Each unit has a complete digital footprint, supporting warranty claims and certifications. - Remote Control and Virtual Simulation

Engineers test parameter changes in the digital twin environment before applying them on the shop floor.

Conclusion

By adopting the IoT Digital Twin for Product Manufacturing, manufacturers of solar panels, batteries, and wind turbine components can achieve smarter, faster, and more accurate production lines. The integration of AI, sensors, and digital modeling transforms traditional production into a futuristic environment of continuous optimization and real-time control.

By EFFE Technology, this digital transformation results in superior product performance, higher efficiency, and stronger market competitiveness—making it an essential step for the future of engineering product manufacturing