IoT Digital Twin for Warehouse Automation—Enhancing Sorter Machine Efficiency and Logistics Flow

Introduction

Modern warehouses rely heavily on automation to handle massive volumes of goods, particularly in sectors like e-commerce, retail, and logistics. Sorter machines play a key role in routing parcels and inventory quickly and accurately. However, ensuring their efficiency, minimizing downtime, and optimizing logistics flow require smart technologies. The IoT Digital Twin for Warehouse Automation creates a live virtual replica of sorter operations, enabling real-time monitoring, predictive maintenance, and data-driven decisions that streamline warehouse operations.

This case study focuses on how a fulfillment center improved its high-speed parcel sorting system using IoT digital twin technology.

Challenges in Warehouse Sorting Operations

- Frequent breakdowns in conveyor belts and diverter arms.

- Misrouting of parcels due to scanner or sensor failure.

- No visibility into real-time machine performance or flow congestion.

- Manual tracking of parcel movement slowing overall dispatch time.

- High energy consumption and inefficient layout utilization.

Process of IoT in Sorter Machine Automation

- Sensing (Data Collection)

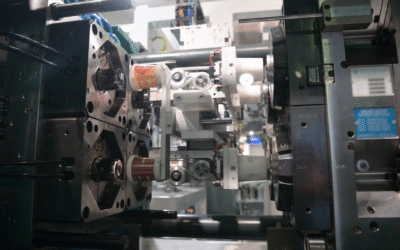

IoT sensors were embedded in diverters, conveyor motors, barcode scanners, parcel weighers, and alignment modules. They captured data on conveyor speed, motor temperature, scanner status, parcel dimensions, and flow density—feeding into the IoT Digital Twin for Warehouse Automation platform.

- Transmission (Data Transfer)

Sensor data was sent over industrial Wi-Fi and MQTT protocols to edge gateways and cloud storage in real time, ensuring zero lag in data flow.

- Data Processing (Edge or Cloud Computing)

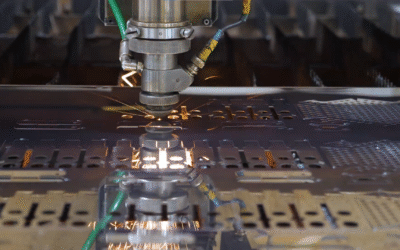

Edge processors handled immediate actions like rerouting during a blockage or slowing belts in case of overload. Cloud-based AI platforms assessed performance trends and forecasted maintenance needs.

- Data Storage

Each parcel’s journey and machine activity logs were recorded in a centralized cloud system. Data was organized by time, section, and SKU ID for traceability and reporting.

- Data Analysis (AI/ML Integration)

AI models predicted potential motor failures based on vibration and temperature. ML algorithms optimized parcel routing sequences, reducing bottlenecks and increasing sorter throughput.

- Decision Making / Action Execution

When a sensor flagged a jam, the system instantly diverted the flow and triggered corrective protocols. Decisions like adjusting belt speed or initiating standby mode were automated based on real-time data.

- User Interface

Warehouse managers monitored a dashboard showing sorter health, real-time parcel tracking, and congestion alerts. Color-coded analytics allowed quick issue identification and response.

- Digital Twin Interface (Remote Monitoring & Control)

The IoT Digital Twin for Warehouse Automation visually replicated the entire sorter system, including all conveyors, scanners, and diverters. Supervisors could simulate parcel flow, assess “what-if” scenarios, and optimize machine configurations remotely.

Results and Impact

| Metric | Before Implementation | After Implementation |

| Sorting Error Rate (%) | 3.7 | 0.8 |

| Machine Downtime (hours/month) | 21 | 5 |

| Average Parcel Processing Time (sec) | 28 | 17 |

| Energy Usage (kWh/day) | 1800 | 1300 |

| Throughput (Parcels/hour) | 7,000 | 10,500 |

- Sorting accuracy improved by 78%, minimizing dispatch delays and customer complaints.

- Machine uptime significantly increased due to predictive maintenance and smart alerts.

- Parcel processing time reduced, enabling faster daily fulfillment.

- Energy savings achieved by dynamic speed control and standby management.

- Overall throughput boosted, meeting peak demand with ease.

Benefits of IoT Digital Twin for Warehouse Automation

- Real-Time Equipment Visibility

Live data from sensors enables proactive intervention, avoiding costly disruptions. - Predictive Maintenance

Machine learning detects component wear and schedules maintenance before breakdowns occur. - Dynamic Flow Optimization

Adjusts conveyor speeds and routing strategies based on parcel volume and priority. - Improved Accuracy and Customer Experience

Reduces human error and mis-sorting, ensuring timely and correct deliveries. - Data-Driven Layout Planning

Helps plan warehouse expansion or reconfiguration using historical performance data. - Remote Monitoring & Control

Facility managers can monitor operations across multiple shifts or sites using the digital twin interface.

Conclusion

The implementation of the IoT Digital Twin for Warehouse Automation in sorter machine operations has transformed traditional logistics into a smarter, faster, and more reliable system. With the power of real-time monitoring, intelligent analysis, and digital replication, warehouses can now ensure consistent high performance, adapt to demand fluctuations, and deliver operational excellence.

This technology is no longer optional—it is vital for any logistics-driven business striving to stay competitive in today’s high-volume, fast-delivery environment. For more content, visit EFFE Technology.