Case Study: IoT Digital Twin for Automobile Industry — Enhancing Transmission Gear Manufacturing

Introduction

In the automobile industry, transmission gears are critical components that demand precision manufacturing to ensure vehicle performance and reliability. Traditional manufacturing methods face challenges related to downtime, quality control, and process inefficiencies. To overcome these, the implementation of IoT Digital Twin for Automobile Industry has become a transformative approach, enabling real-time monitoring, predictive analytics, and process optimization.

This case study explores how the integration of IoT Digital Twin technology improved transmission gear manufacturing, highlighting the detailed IoT process involved.

Challenges in Transmission Gear Manufacturing

- Frequent unplanned downtime of CNC machines.

- Quality defects such as dimensional inaccuracies and surface imperfections.

- Inefficient tool life management leading to increased costs.

- Limited real-time visibility into manufacturing operations.

Process of IoT in Transmission Gear Manufacturing

- Sensing (Data Collection)

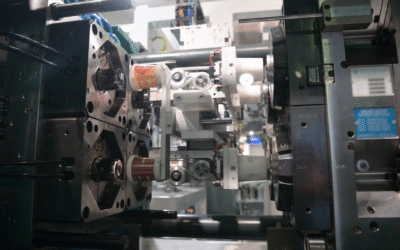

IoT sensors were deployed on critical points of CNC hobbing, grinding, and heat treatment machines. These sensors collected data on vibration, spindle speed, temperature, coolant flow, and clamping force. This constant data stream provided the foundation for the IoT Digital Twin for Automobile Industry by capturing real-world machine and process parameters.

- Transmission (Data Transfer)

Collected sensor data was transmitted securely via industrial IoT gateways over wireless and wired networks to local edge computing devices and cloud servers. This ensured real-time, uninterrupted data flow essential for creating an accurate digital twin environment.

- Data Processing (Edge or Cloud Computing)

At the edge, preliminary data processing filtered and normalized sensor data to reduce latency. Complex computations and long-term analytics were handled on cloud platforms. This hybrid computing approach balanced real-time responsiveness with in-depth analytics needed for predictive maintenance and process optimization.

- Data Storage

Processed data was stored in secure cloud databases with historical logging. This enabled trend analysis and machine learning model training, essential components of the IoT Digital Twin for Automobile Industry strategy to continuously improve manufacturing accuracy and equipment reliability.

- Data Analysis (AI/ML Integration)

AI and machine learning algorithms analyzed incoming data to detect patterns indicating tool wear, machine faults, and quality deviations. Predictive models forecasted potential failures, enabling proactive maintenance scheduling. Quality control simulations were also run within the digital twin to test new process parameters virtually.

- Decision Making / Action Execution

Based on AI insights, automatic alerts were generated for operators and maintenance teams. Machine control systems were configured to adjust operational parameters such as feed rates and coolant flow dynamically. These real-time decisions optimized production without interrupting the manufacturing process.

- User Interface

Operators and engineers accessed interactive dashboards on tablets and desktop systems. These dashboards displayed real-time machine health, production KPIs, and alerts, improving decision-making speed and effectiveness. The user interface was designed to simplify complex data into actionable insights.

- Digital Twin Interface (Remote Monitoring & Control)

The digital twin interface mirrored the physical transmission gear production line, enabling remote monitoring and control. Engineers could simulate process changes, predict outcomes, and control equipment settings from a centralized location. This virtual model was crucial in troubleshooting, training, and continuous improvement initiatives.

Results and Impact

After implementing the IoT Digital Twin for Automobile Industry solution, the transmission gear manufacturing process saw significant improvements:

| Metric | Before Implementation | After Implementation |

| Monthly CNC Machine Downtime | 15 hours | 5 hours |

| Gear Rejection Rate | 4.2% | 1.1% |

| Tool Replacement Frequency | Every 6 days | Every 9 days |

| First-Time Pass Rate | 90% | 97% |

| Inspection Time per Batch | 3 hours | 1.2 hours |

- Predictive Maintenance prevented unexpected breakdowns by forecasting machine issues.

- Quality Control improved dramatically with real-time feedback loops.

- Cost Savings were realized through optimized tool usage and reduced scrap rates.

- Process Agility increased by virtually simulating adjustments on the digital twin before physical implementation.

Benefits of IoT Digital Twin for Automobile Industry in Transmission Gear Manufacturing

Implementing IoT Digital Twin for Automobile Industry in transmission gear manufacturing delivers multiple tangible and strategic benefits:

- Reduced Downtime and Increased Equipment Availability

By continuously monitoring machine health through IoT sensors and leveraging predictive analytics, manufacturers can detect early signs of equipment wear or faults. This proactive maintenance strategy, enabled by the digital twin, reduces unplanned downtime significantly, ensuring higher equipment availability and smoother production schedules. - Improved Product Quality and Consistency

The IoT Digital Twin for Automobile Industry provides real-time visibility into production parameters, enabling quick identification and correction of deviations that could lead to defects. This ensures tighter control over gear dimensions, surface finish, and hardness, resulting in higher first-time pass rates and lower scrap. - Optimized Tool Usage and Cost Savings

With AI-driven insights on tool wear and process conditions, manufacturers can optimize tool life—replacing cutting tools or grinding wheels only when truly necessary. This reduces tooling costs and minimizes waste, contributing to overall cost-efficiency. - Accelerated Process Innovation and Flexibility

The digital twin’s virtual simulation capabilities allow engineers to experiment with new machining parameters, tool geometries, or heat treatment profiles without disrupting the actual production line. This speeds up process development and helps the factory adapt quickly to evolving automobile industry demands, including electric vehicle components. - Enhanced Decision-Making and Operator Efficiency

Through intuitive dashboards and remote monitoring interfaces, operators and managers gain instant access to actionable data. The IoT Digital Twin for Automobile Industry empowers staff with predictive alerts and performance insights, enabling faster and more informed decisions, reducing human errors, and improving workforce productivity. - Scalability towards Smart Factory Goals

The successful integration of IoT Digital Twin technology acts as a foundation for broader Industry 4.0 initiatives. It supports future scalability by facilitating connectivity with other smart systems such as warehouse automation, supply chain analytics, and enterprise resource planning (ERP).

Conclusion

The integration of IoT Digital Twin for Automobile Industry in transmission gear manufacturing has revolutionized traditional processes by enabling smarter, data-driven production. The detailed IoT process—from sensing and data transmission to AI-powered decision-making and remote digital twin control—has enhanced machine reliability, product quality, and operational efficiency.

This case underscores the transformative potential of IoT Digital Twin for Automobile Industry applications in complex manufacturing environments, marking a significant step towards the smart factory of the future.