Overview

This project involved developing a comprehensive Factory Virtual Tour for a food manufacturing plant using Virtual Reality Factory Tour, virtual factories, and virtual manufacturing technologies.

Project Requirement

The client, a large-scale food manufacturing organization, faced increasing challenges with physical factory visits due to safety regulations, operational downtime, and travel constraints. They required a Factory Virtual Tour that could replace in-person visits while maintaining transparency and engagement.

Key requirements included:

- A realistic Virtual Reality Factory Tour covering the entire production lifecycle

- Accurate representation of processes through virtual manufacturing

- A scalable solution to showcase virtual factories for clients, auditors, and trainees

The objective was to create a future-ready Factory Virtual Tour that could serve marketing, training, compliance, and sales purposes.

Project Planning

The planning phase focused on aligning business goals with user experience and technical feasibility. Multiple stakeholder workshops were conducted to understand production processes, quality checkpoints, and compliance requirements.

Planning activities included:

- Mapping the factory layout and process flow for the Factory Virtual Tour

- Identifying key storytelling elements within the Virtual Reality Factory Tour

- Structuring the virtual manufacturing experience into modular, reusable sections

- Establishing performance benchmarks for large-scale virtual factories

This structured planning ensured the Factory Virtual Tour would be both technically accurate and commercially impactful.

Project Process & Execution

- Data Collection & Factory Analysis : CAD drawings, equipment specifications, SOPs, and process documents were collected. Real-world visuals were captured to ensure authenticity in the Virtual Reality Factory Tour.

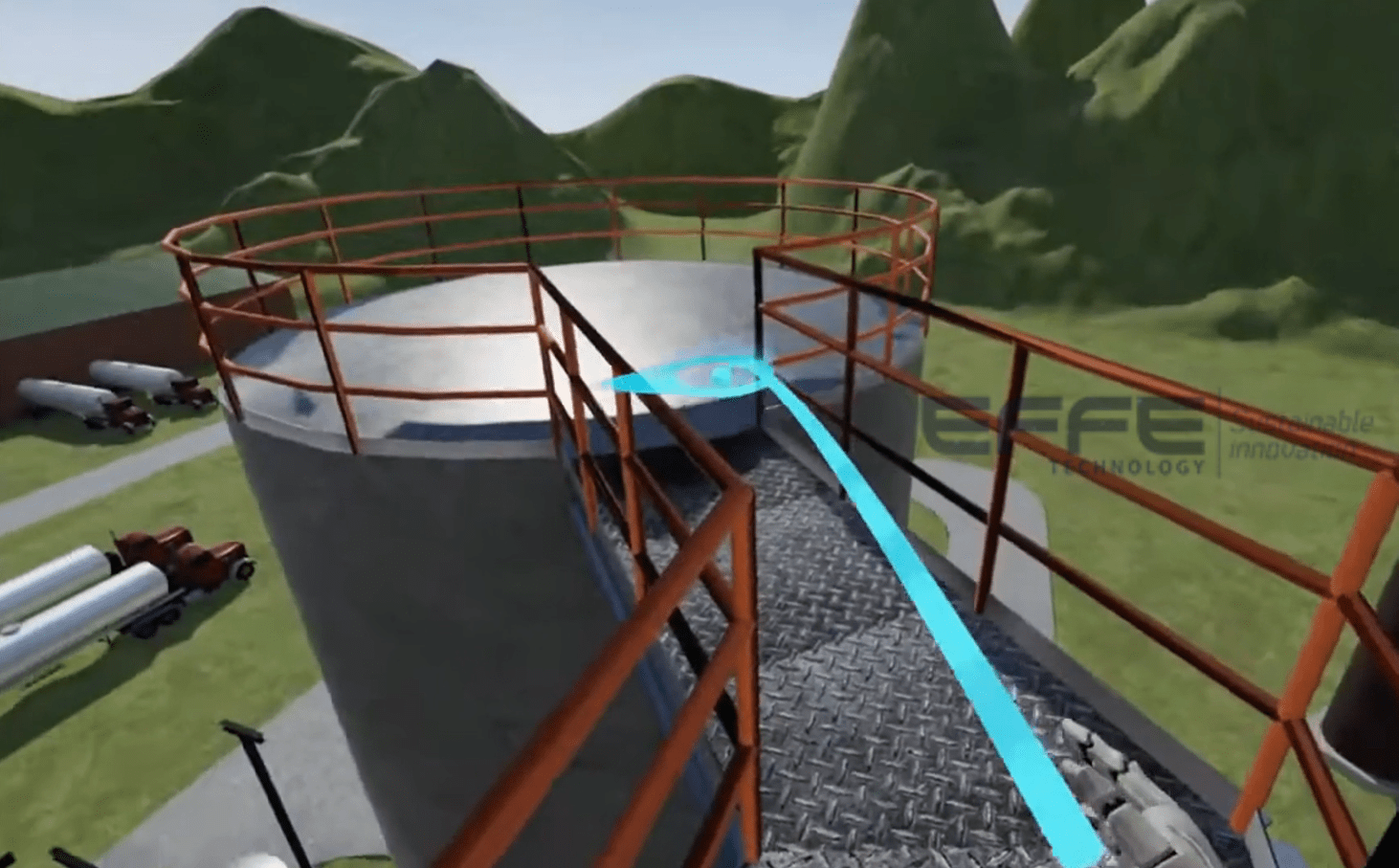

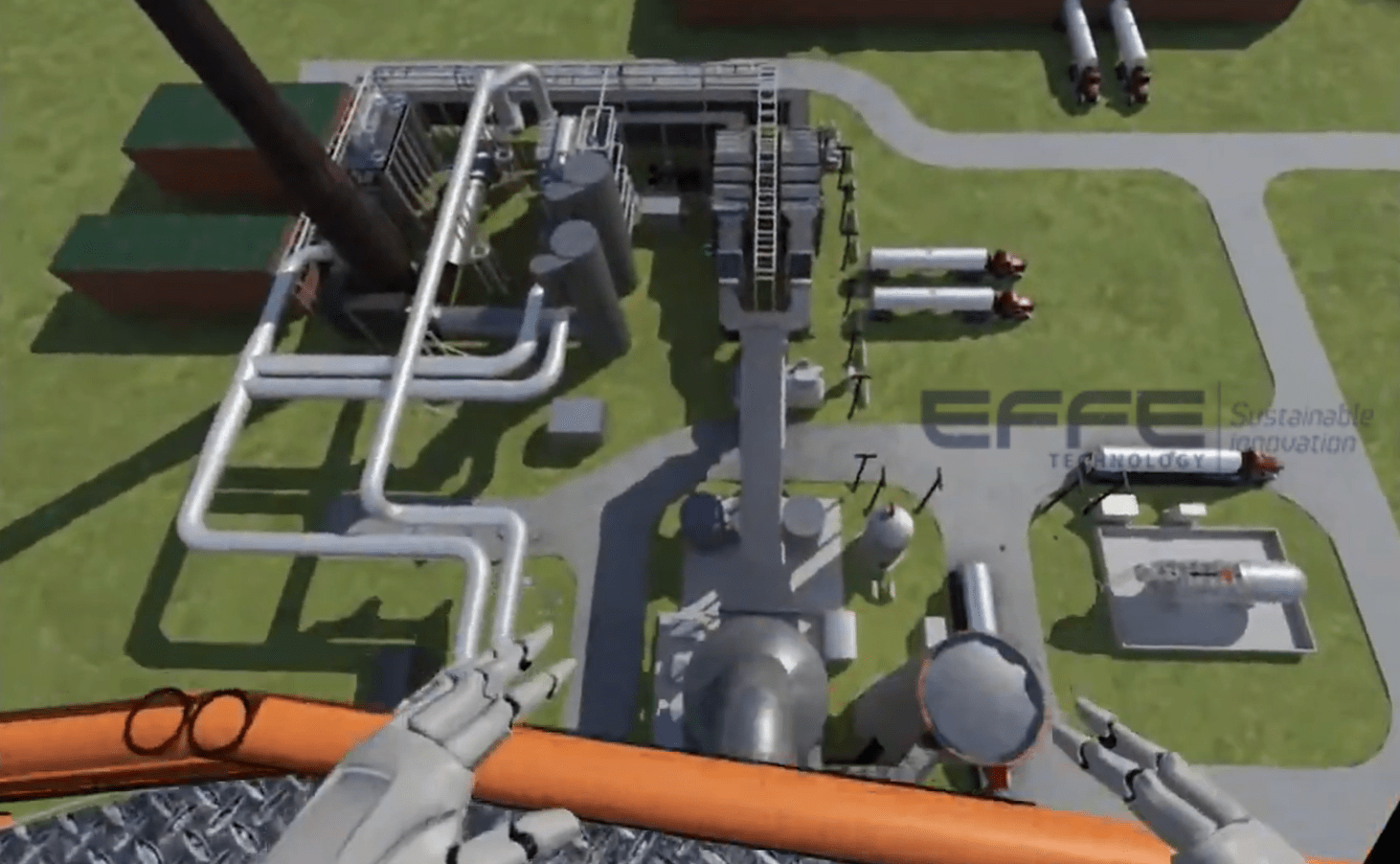

- 3D Modeling & Digital Twin Creation : A high-fidelity 3D model of the facility was created, forming the foundation of the Factory Virtual Tour. Each machine and process was modeled to reflect real operational behavior, enabling true virtual manufacturing visualization.

- Experience Design & Interaction : Interactive hotspots, guided walkthroughs, and process explanations were added. Users could explore virtual factories freely or follow a guided path through the Virtual Reality Factory Tour.

- Integration & Optimization : The experience was optimized for smooth performance across devices. Data layers were integrated to enhance learning and operational clarity within the Factory Virtual Tour.

- Testing & Deployment : The solution underwent multiple rounds of validation with engineering and quality teams before deployment across web, VR, and presentation systems.

Challenges

- Process Complexity

Representing complex manufacturing operations accurately within a Factory Virtual Tour was challenging.

Solution: Modular virtual manufacturing design ensured clarity without overwhelming users. - Performance Optimization

Large virtual factories can impact performance on lower-end devices.

Solution: Optimized assets ensured a smooth Virtual Reality Factory Tour - Compliance & Data Sensitivity

Certain areas required restricted visibility.

Solution: Controlled access layers within the Factory Virtual Tour maintained compliance.

Key Learnings

- A well-designed Factory Virtual Tour significantly reduces dependency on physical visits

- Virtual Reality Factory Tour experiences improve engagement and knowledge retention

- Virtual manufacturing enhances understanding of complex industrial processes

- Scalable virtual factories provide long-term ROI across departments

Client Deliverables

- End-to-end Factory Virtual Tour platform

- Immersive Virtual Reality Factory Tour with guided navigation

- Interactive virtual manufacturing modules

- Digital Twin–enabled virtual factories visualization

Conclusion

The Factory Virtual Tour successfully transformed a physical manufacturing facility into a powerful digital experience. By combining Virtual Reality Factory Tour, virtual manufacturing, and virtual factories, the client achieved higher engagement, improved operational transparency, and reduced costs associated with physical visits.