Overview

The client needed a way to improve training, design understanding, and operational workflows without relying on physical prototypes. We delivered solutions through a Virtual reality manufacturing company, providing interactive 3D simulations and immersive VR experiences. This approach enhanced learning, reduced errors, and increased manufacturing efficiency.

Client Overview

The client is a leading industrial manufacturer with complex machinery and processes. They sought a scalable solution to train staff, communicate designs, and optimize production workflows while reducing risk and costs.

The Problem

Physical prototypes and 2D blueprints were not enough to explain complex machinery and workflows. On-site training was risky, costly, and time-consuming. The client required a solution from a Virtual reality manufacturing company to visualize operations interactively and safely.

Project Requirements

Immersive visualization of machinery and assembly processes

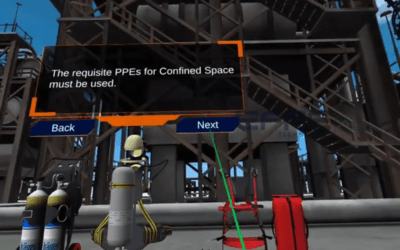

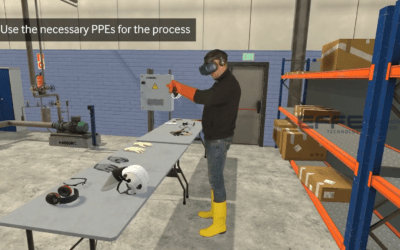

Interactive 3D simulations compatible with VR devices

Support for operator training, design verification, and presentations

High-fidelity rendering for marketing and internal use

Integration of AR/VR in manufacturing for efficiency and safety

Strategy & Planning

We mapped critical machinery and operational processes to create an interactive simulation plan. Using a Virtual reality manufacturing company framework, we designed exploded views, digital twin simulations, and immersive sequences for training, marketing, and design collaboration.

Process & Execution

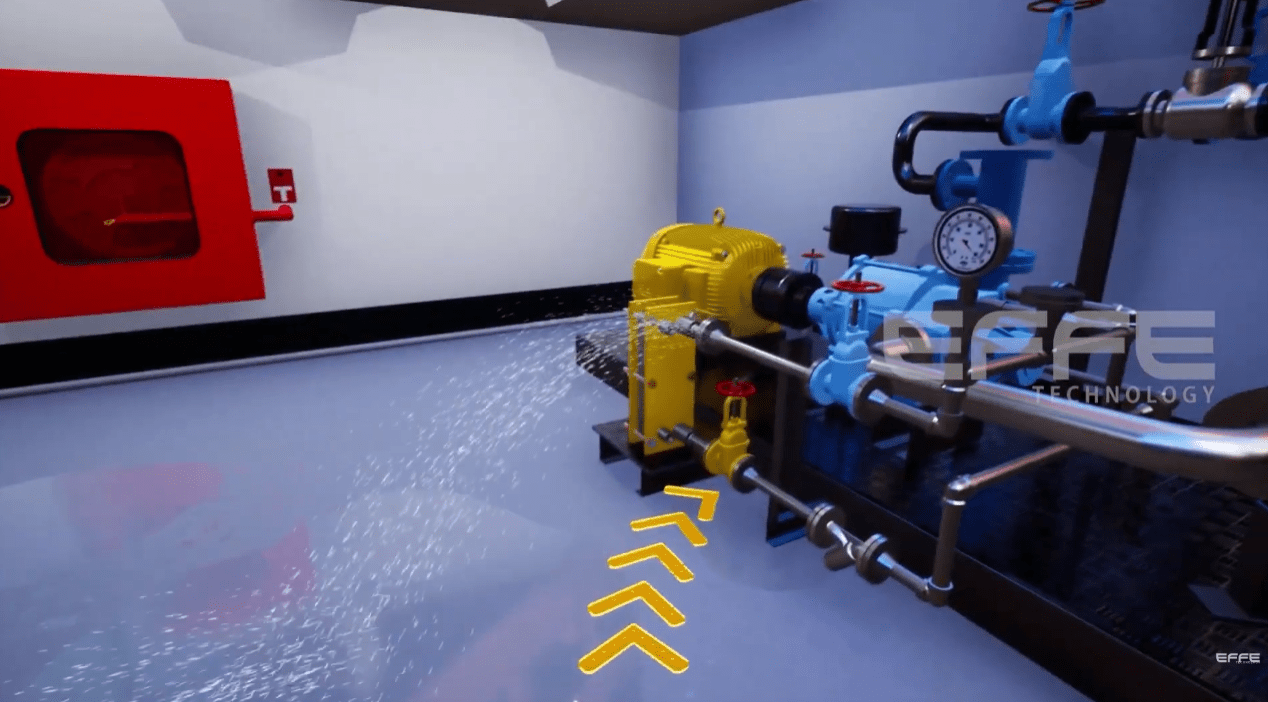

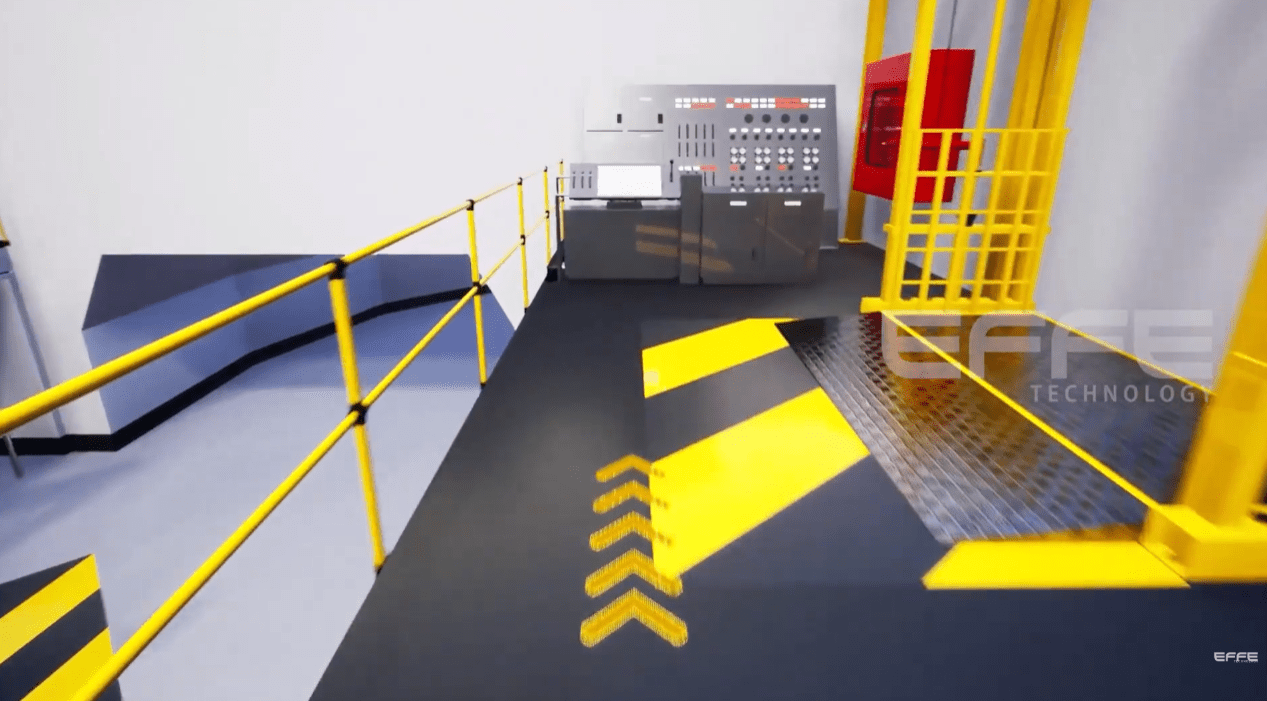

High-resolution 3D models were combined with VR for manufacturing to create interactive, immersive experiences. Exploded views, x-ray renderings, and digital twin simulations allowed users to explore machinery and processes safely. The final product was optimized for both VR devices and web platforms.

Challenges & Key Learnings

Rendering complex mechanical assemblies in immersive 3D

Ensuring intuitive navigation for all users

Optimizing VR simulations for multi-platform accessibility

Key learning: AR/VR in manufacturing significantly accelerates understanding, reduces training time, and improves design collaboration.

Final Deliverables

Interactive Virtual reality manufacturing company simulation

3D VR walkthroughs of machinery and operational workflows

Web and VR-compatible formats for training, presentations, and marketing

Digital twin simulations supporting real-time process analysis

Results & Business Impact

Reduced training and prototype costs

Improved understanding of complex machinery and workflows

Enhanced collaboration between design, engineering, and operations teams

Faster onboarding and higher operational accuracy

The project successfully showcased the client’s operations using Virtual reality manufacturing company solutions and VR for manufacturing applications.

Conclusion

By implementing a Virtual reality manufacturing company solution, the client transformed complex industrial training and design visualization into safe, immersive, and highly interactive experiences. AR/VR in manufacturing improved learning, efficiency, and operational decision-making.