Overview

The client needed to visualize complex industrial workflows and train staff without halting production. We delivered Industrial Processes VR Visualization solutions that recreate entire manufacturing processes virtually. This immersive approach improved operational understanding, reduced errors, and enhanced training efficiency.

Client Overview

The client is a leading industrial manufacturer seeking scalable solutions for workflow visualization, employee training, and process optimization. They aimed to adopt cutting-edge VR technology to simulate real production environments safely.

The Problem

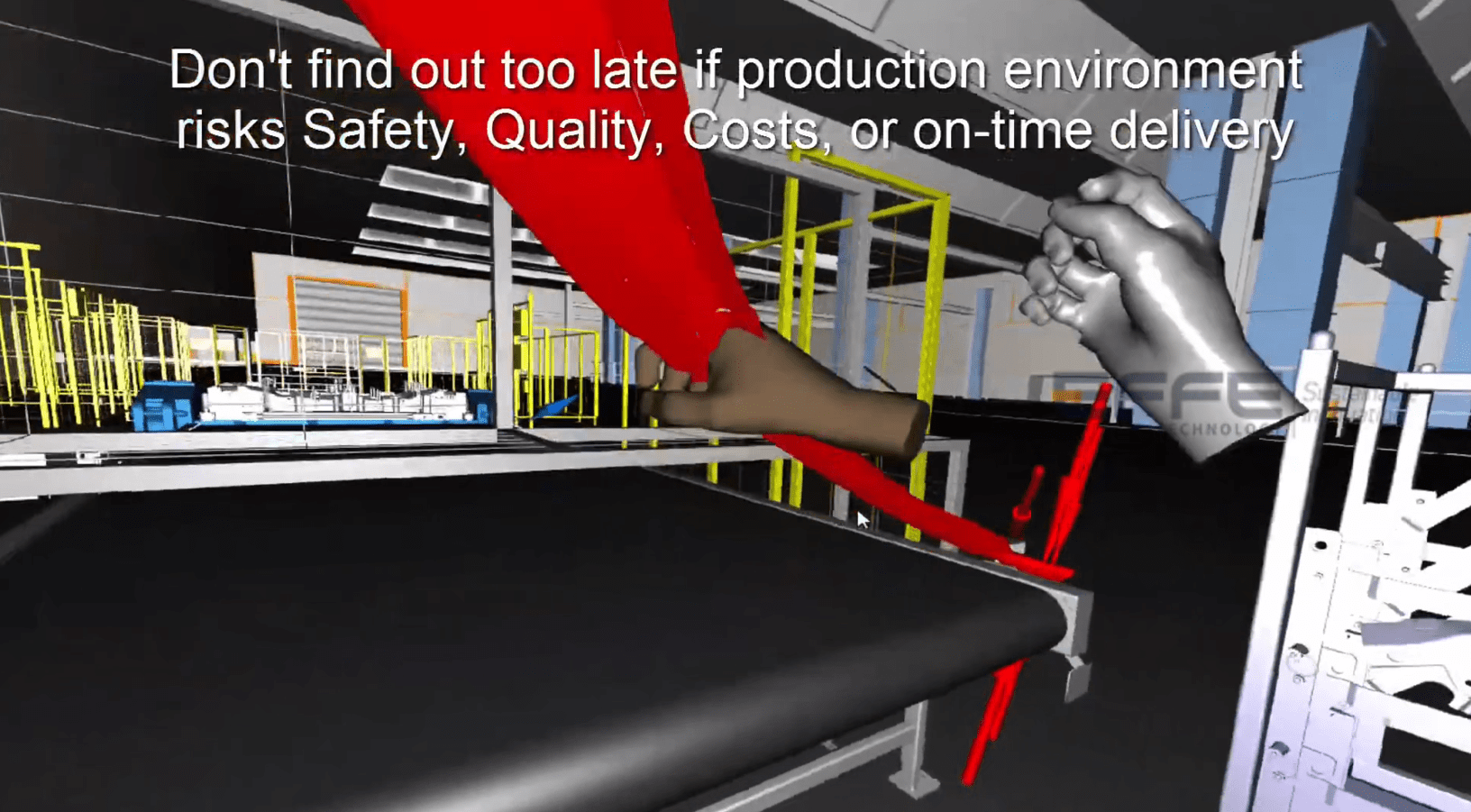

Traditional training and process observation methods could not fully convey complex manufacturing operations. On-site visits were risky and time-intensive, limiting learning and process validation. The client needed Industrial Processes VR Visualization to provide safe, interactive, and repeatable simulations.

Project Requirements

Immersive VR visualization of industrial workflows

Accurate VR Manufacturing Process simulations for operational understanding

Safe and interactive training environments

Compatibility with VR devices and desktops

Scalable solution for multiple manufacturing units

Strategy & Planning

We mapped critical production lines and workflows to create interactive VR simulations. Using Industrial Processes VR Visualization: the project highlighted operational sequences, safety checkpoints, and process efficiencies. Storyboards ensured clarity, engagement, and intuitive navigation for trainees and management teams.

Process & Execution

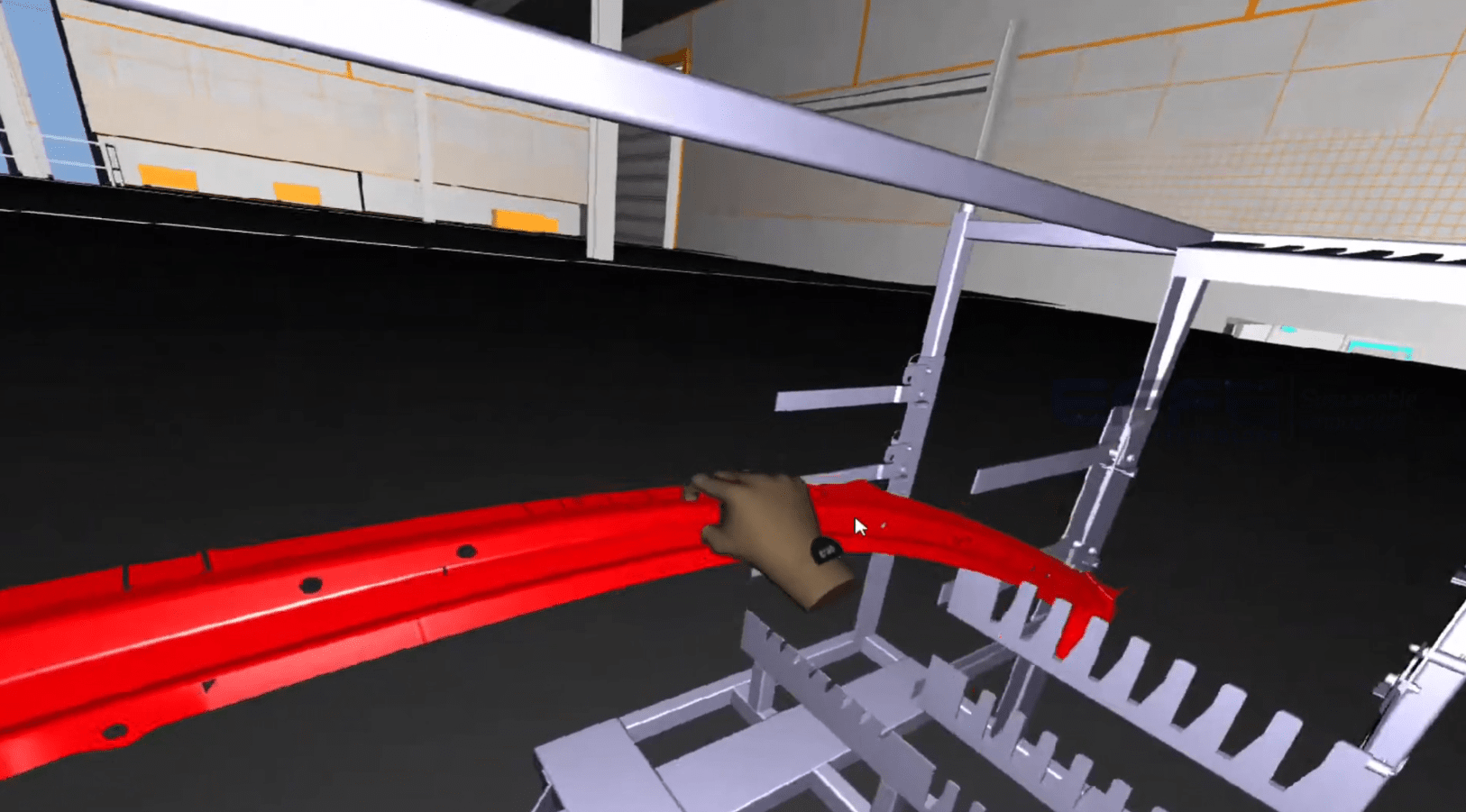

High-resolution 3D models and interactive VR environments were created to replicate machinery, assembly lines, and production sequences. The solution combined VR Manufacturing Process simulations with Process Simulation VR for training, planning, and operational analysis. The VR environment allowed users to explore, interact, and understand processes virtually while maintaining safety.

Challenges & Key Learnings

Capturing complex industrial operations accurately in VR

Maintaining realism while ensuring interactive learning

Optimizing VR for different devices and platforms

Key learning: Immersive Industrial Processes VR Visualization significantly improves operational understanding and reduces training time.

Final Deliverables

Full Industrial Processes VR Visualization simulation of production workflows

Interactive VR modules compatible with VR devices and desktops

Training-ready simulations integrating VR Manufacturing Process best practices

Analytical tools for tracking performance and workflow comprehension

Results & Business Impact

Reduced dependency on physical observation and on-site training

Improved operational understanding and employee performance

Enhanced process validation and planning

Scalable VR solution across multiple manufacturing units

The project successfully implemented Industrial Processes VR Visualization, VR Manufacturing Process, and Process Simulation VR, delivering measurable efficiency and safety improvements.

Conclusion

By adopting Industrial Processes VR Visualization, the client transformed traditional process training into an interactive, safe, and immersive experience. This approach improved workforce efficiency, reduced operational risks, and supported better decision-making in production planning.