Overview

The client needed a solution to train employees on complex assembly lines safely and efficiently. We delivered VR Assembly Training solutions enhanced with AI guidance, enabling workers to practice procedures in a risk-free environment. This immersive experience increased engagement, reduced errors, and accelerated skill acquisition.

Client Overview

The client is a leading manufacturing company aiming to optimize employee training, reduce operational errors, and scale workforce competency. Their goal was to implement a scalable, immersive solution that integrates modern technologies like AI Powered VR Training for Manufacturing Industry.

The Problem

Traditional on-site training was time-consuming, risky, and inconsistent. Employees had limited opportunities to practice critical assembly tasks, resulting in mistakes and production delays. The client required VR Assembly Training to replicate real-world scenarios in a controlled, interactive environment.

Project Requirements

Provide immersive VR assembly training for employees

Integrate AI guidance to enhance learning outcomes

Simulate real manufacturing workflows accurately

Ensure compatibility with VR devices and digital platforms

Improve efficiency, reduce errors, and scale training across multiple facilities

Strategy & Planning

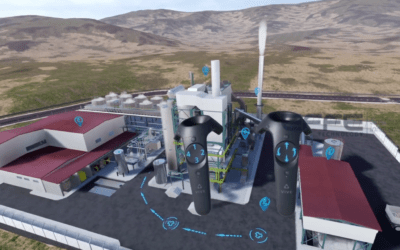

We mapped the key assembly procedures, critical safety points, and operational workflows. The solution leveraged AI Powered VR Training for Manufacturing Industry principles to guide trainees interactively, while enabling managers to track progress. The VR design included realistic simulation of equipment, workflow steps, and safety alerts.

Process & Execution

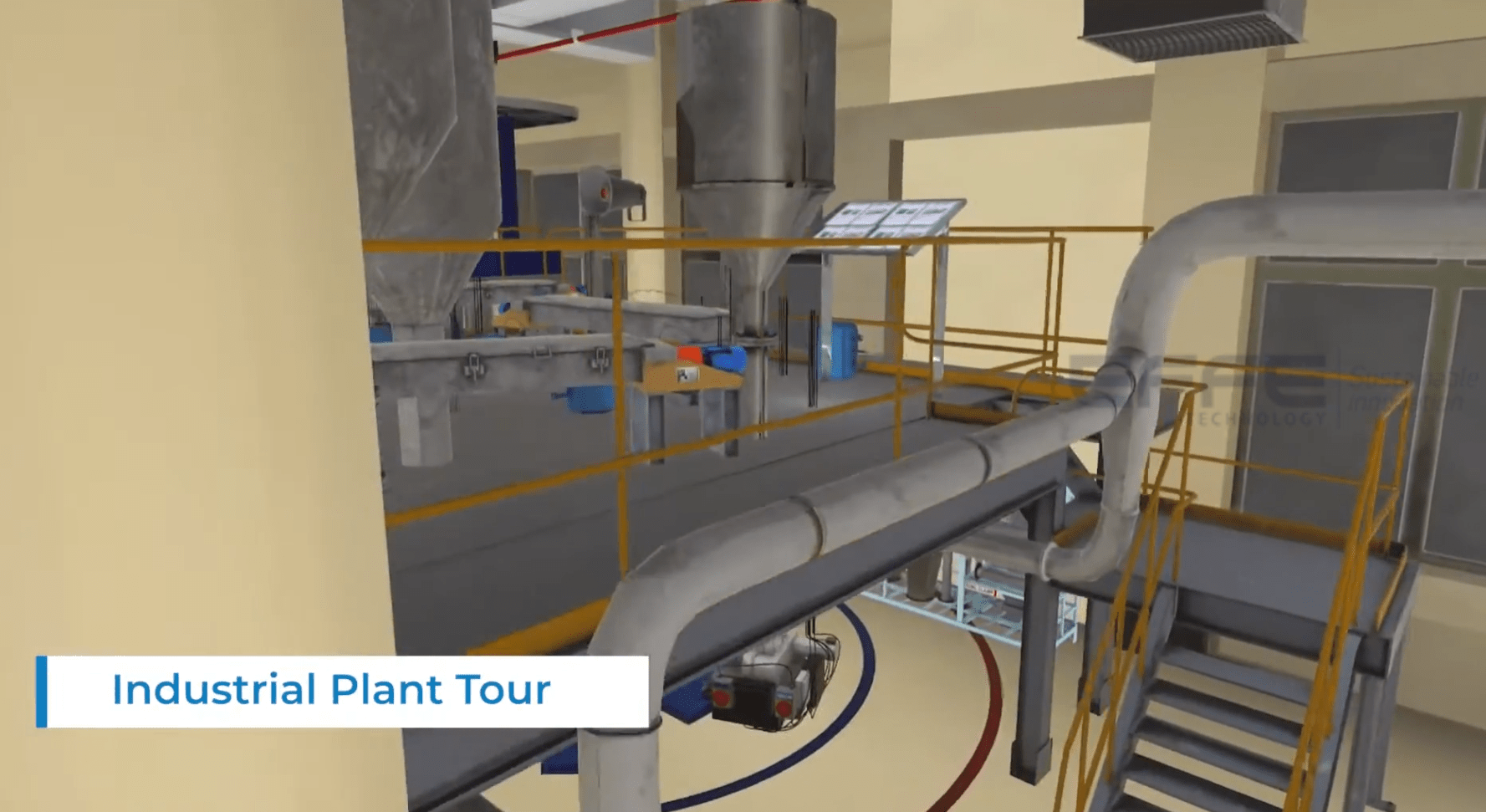

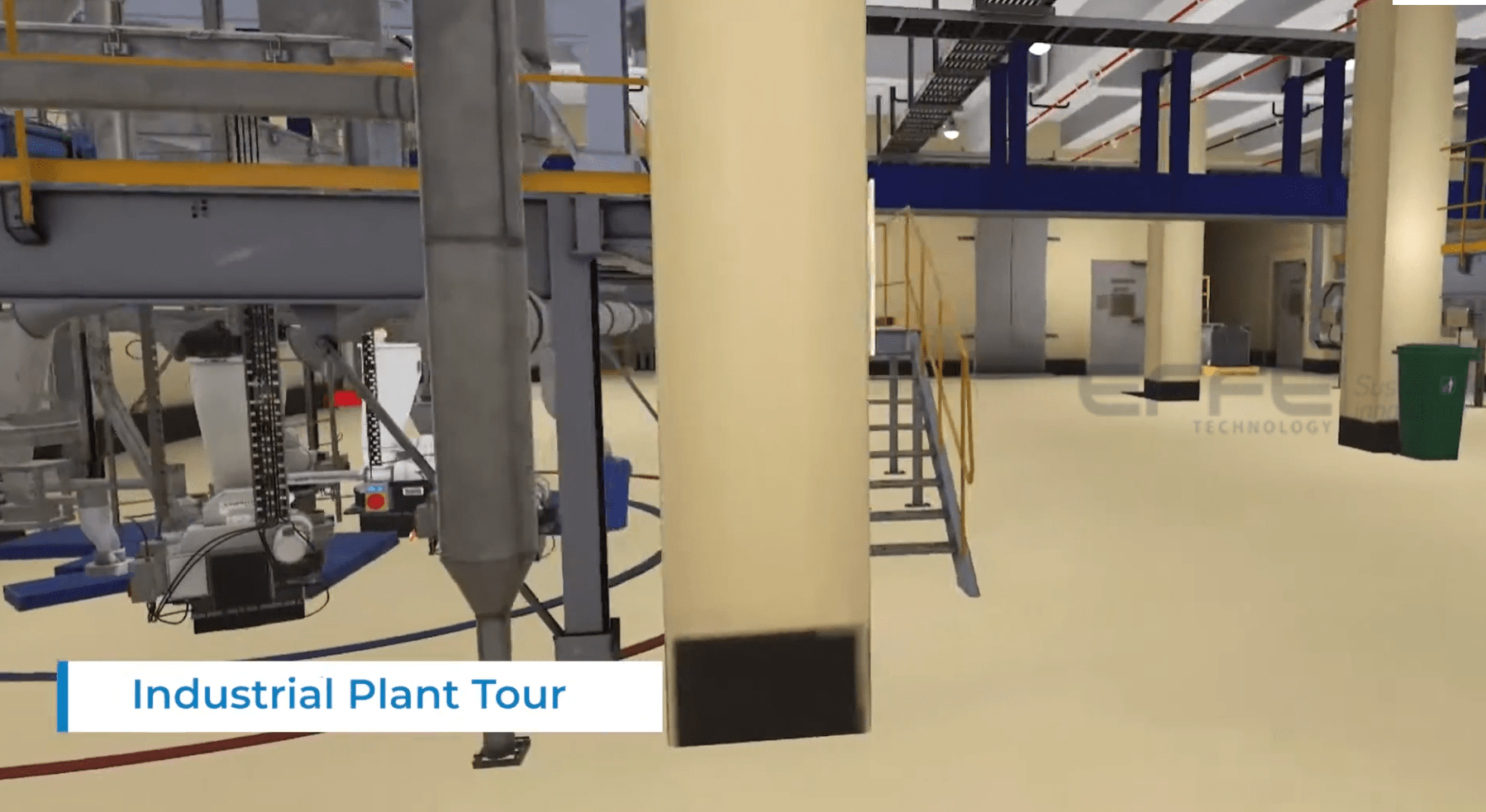

High-resolution 360-degree VR environments were created to simulate assembly lines. Trainees could perform procedures step-by-step, receiving AI guidance for each critical task. The VR modules were also aligned with VR Automation Engineering workflows to simulate automated processes in real-time. User comfort, visual clarity, and interactive elements were prioritized to maximize training effectiveness.

Challenges & Key Learnings

Capturing complex assembly line processes in a VR environment

Maintaining realism while keeping interactions intuitive

Balancing AI guidance with learner autonomy

Key learning: Combining VR Assembly Training with AI guidance enhances retention, reduces mistakes, and speeds up skill acquisition.

Final Deliverables

Complete VR Assembly Training modules for employees

AI-guided interactive simulations compatible with VR and desktop platforms

Training analytics dashboards for performance tracking

Scalable solution integrating VR Automation Engineering workflows

Results & Business Impact

Reduced on-site training costs and risks

Increased employee skill retention and efficiency

Faster onboarding for new hires

Scalable, repeatable training across multiple manufacturing sites

The project successfully positioned the client as a leader in modern industrial training using VR Assembly Training and AI Powered VR Training for Manufacturing Industry.

Conclusion

By implementing VR Assembly Training, the client transformed traditional training into a safe, interactive, and measurable experience. Combining VR with AI and VR Automation Engineering ensured higher engagement, faster skill acquisition, and reduced operational errors.