Overview

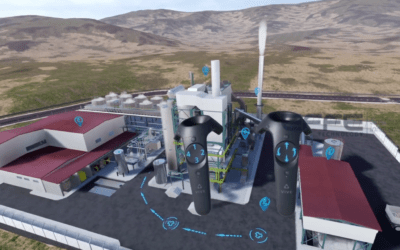

The client wanted to modernize how industrial environments, safety procedures, and operational workflows were understood by employees and stakeholders. We delivered an Industrial VR solution that allowed users to experience real industrial conditions virtually, improving understanding, safety awareness, and engagement without physical risk.

Client Overview

The client operates within a complex industrial environment where safety, accuracy, and process understanding are critical. They were looking for an experienced Industrial VR Company that could create immersive solutions for training, visualization, and operational awareness.

The Problem

Conventional training methods such as classroom sessions, manuals, and limited site walkthroughs failed to communicate real-world industrial challenges. On-site exposure carried safety risks and high costs. The client required Industrial VR to recreate realistic environments in a controlled and repeatable way.

Project Requirements

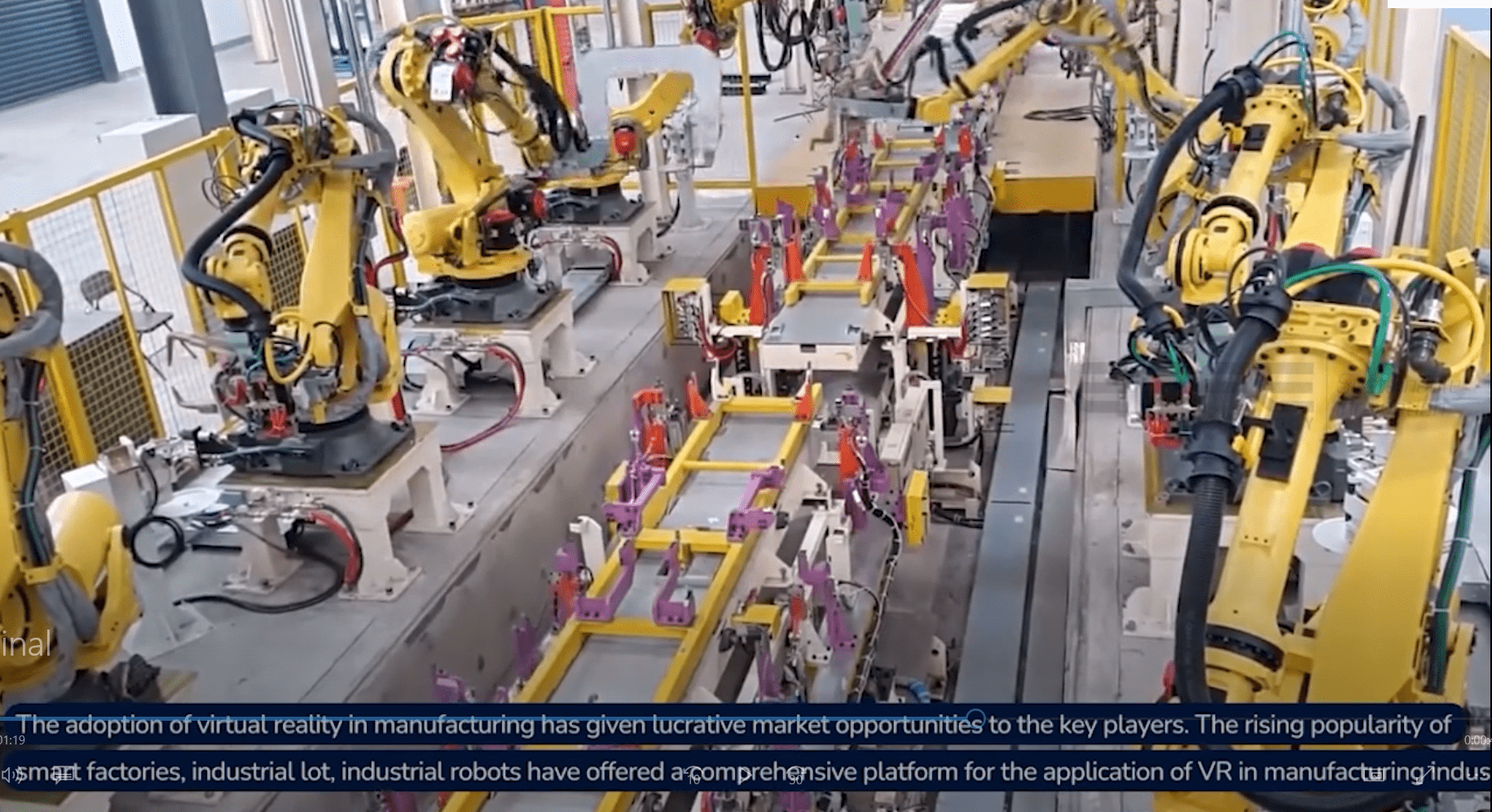

Immersive visualization of industrial environments

Safe training without interrupting live operations

Easy-to-understand experience for workers and management

Scalable solution usable across departments

Reliable support from an Industrial VR Company

Strategy & Planning

We identified high-risk and high-value operational areas and mapped them into immersive virtual scenarios. The solution was designed around Industrial VR Services that prioritize realism, clarity, and ease of navigation. Planning focused on user flow, safety accuracy, and measurable learning outcomes.

Process & Execution

Using detailed 3D modeling and interactive VR environments, we recreated real industrial sites and workflows. Users could explore processes, understand safety procedures, and identify risks virtually. The project was executed using proven Industrial VR Services, ensuring performance, comfort, and accuracy across devices.

Challenges & Key Learnings

Accurately replicating complex industrial layouts

Making VR easy to use for first-time users

Balancing realism with training clarity

Key learning: Well-designed Industrial VR experiences significantly improve retention, safety awareness, and operational confidence.

Final Deliverables

Fully immersive Industrial VR experience

Interactive operational and safety simulations

Multi-platform VR compatibility

Structured modules delivered by an Industrial VR Company

Results & Business Impact

Improved safety awareness and risk recognition

Faster onboarding and standardized training

Reduced dependency on physical site visits

Strong adoption of Industrial VR Services across teams

Conclusion

By implementing Industrial VR, the client transformed traditional industrial training into an immersive, safe, and repeatable experience. With expert Industrial VR Services, the organization achieved better understanding, reduced risk, and improved operational efficiency.