Project Title:

Immersive VR Aircraft Maintenance Training Demo for a Leading Aerospace Manufacturer

Short Description:

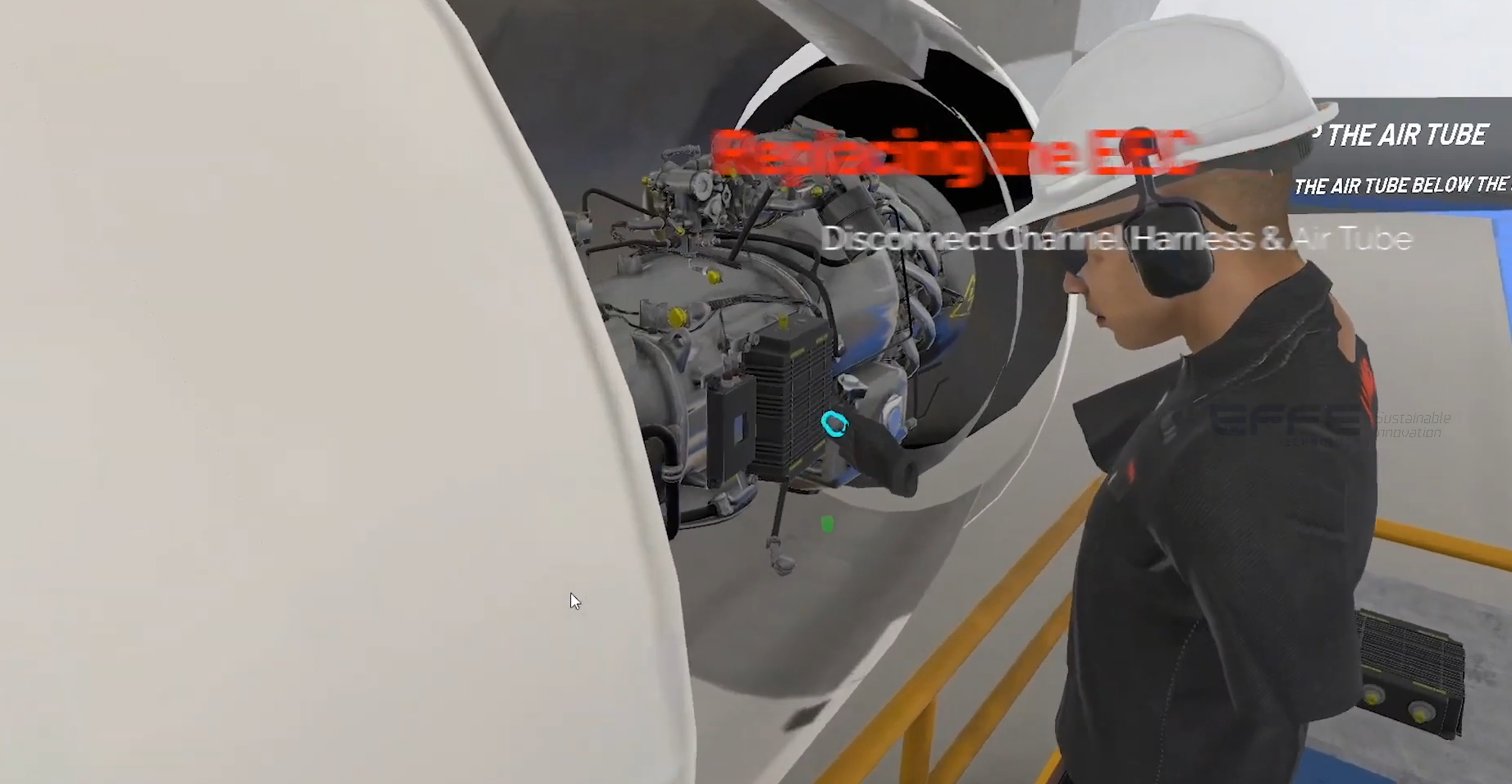

Our client, a global manufacturing company providing products, services, and engineering solutions for commercial aircraft, required an advanced and interactive VR solution to demonstrate how virtual reality is reshaping aviation maintenance training. The goal was to create a high-impact demo video showcasing VR aircraft maintenance training and Aircraft maintenance VR simulation as next-gen tools for safety, performance, and operational efficiency.

Project Requirement:

The client wanted a VR demo that visually explains how immersive technology is transforming technician training in the aviation industry. Their requirement included:

-

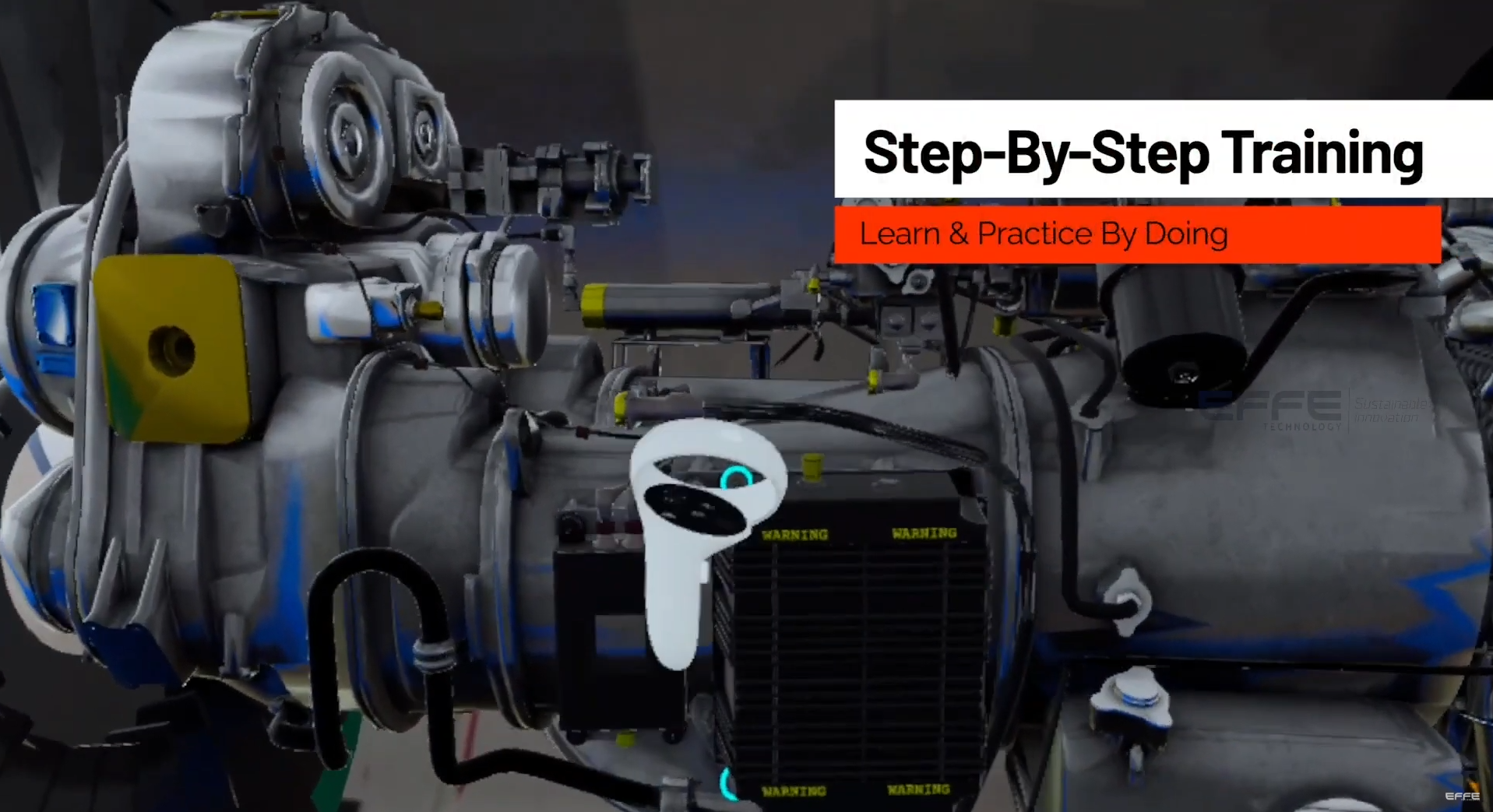

Demonstrating how VR aircraft maintenance training works in real-time

-

Highlighting interactive Aircraft maintenance VR simulations such as component inspection, troubleshooting, and procedural tasks

-

Showcasing benefits like safety improvement, skill enhancement, and reduced downtime

-

Creating a realistic digital aircraft environment

-

Making the demo suitable for marketing, customer pitches, and internal presentations

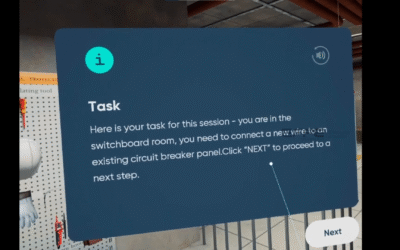

They wanted the video to serve as a snapshot of how VR can modernize the traditional maintenance learning process.

Project Planning:

Our team began with a structured plan:

-

Understanding Aircraft Maintenance Workflows

We studied standard MRO procedures, safety protocols, and critical maintenance tasks performed by technicians. -

Content Research

Research included aviation training manuals, mechanic workflows, and real-world maintenance scenarios to ensure authenticity. -

Storyboard & Script Creation

We designed a storyboard that visually demonstrates step-by-step VR interactions, from aircraft inspection to component-level maintenance using Aircraft maintenance VR simulation tools. -

3D Environment Planning

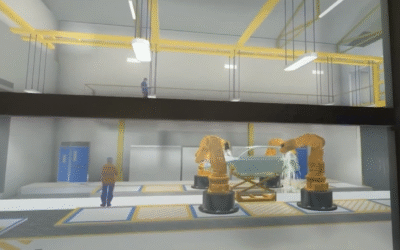

The virtual aircraft hangar, interior and exterior views, and mechanical components were mapped out to create a highly detailed user experience.

Project Process & Execution:

-

Environment & Asset Modelling

We created a realistic aircraft model, engine components, landing gear systems, and cockpit panels to be used in the VR aircraft maintenance training module.

-

Interaction Design

We designed VR interactions such as:-

Virtual tool selection

-

Component disassembly

-

Fault detection

-

Safety checks

These interactions showcased how Aircraft maintenance VR simulation enhances hands-on learning.

-

-

Animation & Simulation

Dynamic animations demonstrated common maintenance tasks—engine diagnostics, wiring checks, fluid-level inspection, and sensor alignment. -

Integration of Training Scenarios

The final video included multiple VR-based training situations like:-

Hazard identification

-

Step-by-step maintenance procedure guidance

-

Real-time feedback for technicians

-

-

Rendering & Final Output

High-quality renders were produced to highlight the immersive realism of VR in aviation maintenance.

Challenges & Learning:

-

Accuracy of Aircraft Components

Since aviation training requires precision, every 3D asset had to match real-world scale and functionality. Ensuring engineering accuracy was a major challenge. -

Complex Procedures Visualization

Some maintenance tasks involve multiple steps; simplifying these without losing authenticity required careful planning. -

Client On-Site Visit

During the project, our team visited the client’s facility to understand real maintenance environments. This visit helped us fine-tune the VR aircraft maintenance training flow to match real technician workflows. -

Balancing Detail and Performance

VR demands high-fidelity visuals without affecting performance. Optimizing the simulations was a major learning experience.

Client Deliverables:

-

A complete VR demonstration video

-

High-resolution 3D aircraft maintenance environment

-

Interactive Aircraft maintenance VR simulation showcases

-

Marketing-friendly visuals explaining VR’s impact on aviation learning

-

VR-ready assets for future integrations