Project Title:

Immersive VR Engine Assembly Training System for Automotive Workforce

Short Description:

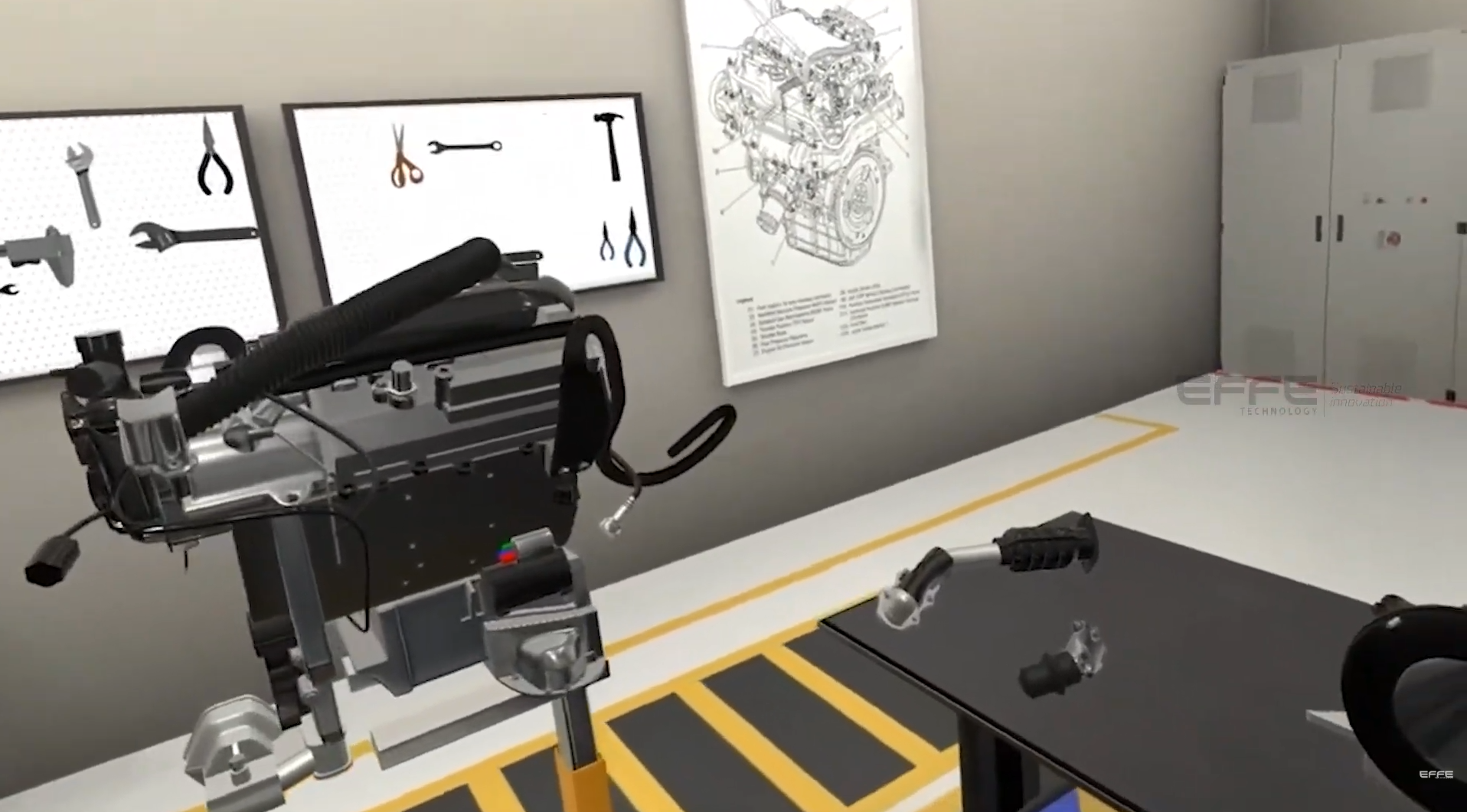

This project focused on creating a fully immersive Virtual engine assembly training platform for a leading car manufacturing company. The goal was to replace traditional, costly, and time-consuming training methods with an interactive Automotive VR training solution. Through realistic 3D models, guided instructions, and real-time feedback, employees were able to learn engine assembly in a completely virtual environment—reducing risk, improving efficiency, and ensuring standardised skill development across the entire workforce.

Project Requirement:

The client wanted a modern training system that simplified the engine assembly learning process for new hires and existing staff. Their traditional training approach required physical engines, expert supervision, and repeated demonstrations. This led to higher costs, parts wear-and-tear, inconsistent outcomes, and limited hands-on practice.

They needed a solution that:

-

Provides realistic engine assembly experience without physical components

-

Offers guided, practice, and assessment-based training modes

-

Enables unlimited practice without material wastage

-

Ensures safety and reduces beginner mistakes

-

Standardizes training across multiple plants

-

Supports future scalability with more engine models

The client specifically aimed to adopt Virtual engine assembly training to improve training outcomes, reduce operational costs, and accelerate workforce readiness.

Project Planning:

Our planning phase involved a deep understanding of the client’s engine assembly workflow. We began by conducting meetings with senior engineers and technical trainers to break down the exact steps of assembly, including tools, torque values, sequencing, and safety protocols.

Key planning tasks included:

Requirement Gathering: Collecting technical details, references, and engine specifications.

Workflow Mapping: Documenting every step of the engine assembly process.

3D Asset Planning: Listing all engine parts, tools, and animations required.

VR System Architecture: Designing the complete structure for Automotive VR training including user flow, modes, and interaction patterns.

Timeline Setup: Dividing the project into modeling, development, integration, testing, and deployment milestones.

This structured planning ensured accuracy, real-world simulation, and timely execution.

Project Process & Execution:

1. High-Precision 3D Modelling

We created detailed 3D models of every engine component based on OEM standards. Each model was optimized for VR to ensure smooth performance.

2. Interaction & Tool Simulation

Engine parts were programmed with interactions like picking, placing, rotating, and tightening. Virtual tools simulated real torque behavior, ensuring training realism.

3. Training Modes Development

Three training modes were built:

-

Learning Mode: Step-by-step guided instructions for beginners

-

Practice Mode: Hands-on assembly without guidance

-

Assessment Mode: Timed skill evaluation with scoring

4. Real-Time Feedback System

The system highlighted incorrect placements, alignment errors, and missing steps, helping trainees learn faster.

5. Testing & Optimization

Rigorous testing ensured accurate hand-tracking, smooth interactions, and easy usability for new users.

6. Deployment & Onboarding

The final VR module was deployed to the client’s training center along with trainer workshops and documentation support.

Challenges & Learning:

Challenges

-

Achieving millimeter-level precision for part alignments

-

Simulating mechanical physics within VR

-

Making the experience intuitive for users with zero VR experience

-

Converting complex engineering instructions into simple VR steps

Learnings

-

Repetition in VR drastically improves employee confidence

-

Gamified learning motivates employees more than traditional training

-

Virtual engine assembly training reduces overall training time

-

Automotive VR training creates a safe environment for complex mechanical learning

Client Deliverables:

-

Complete VR training application

-

Fully modeled 3D engine and tool assets

-

Guided, practice, and assessment training modes

-

Real-time error detection and scoring system

-

Instructor dashboard for monitoring performance

-

Full deployment, documentation, and support