Project Title:

VR Safety Training Module for Electronics Manufacturing Workforce

Short Description:

This project focuses on developing a fully immersive Virtual Reality (VR) training solution for an electronics manufacturing company to enhance employee understanding of workplace safety, operational best practices, and emergency response. The experience introduces high-risk scenarios in a controlled digital environment where workers can learn, practice, and evaluate their knowledge without real-world exposure. The solution demonstrates the increasing adoption of Virtual Reality in electronic industry operations and showcases the effectiveness of VR safety training for electronics industry workforce development.

Project Requirement:

The client, a major electronics manufacturer, faced challenges in maintaining consistent safety training across their growing workforce. New recruits often needed extensive training on:

- Handling sensitive electronic components

- Safety protocols in production lines

- ESD (Electrostatic Discharge) standards

- PPE (Personal Protective Equipment) compliance

- Electrical hazard response

- Machine operation awareness

- Emergency procedures

Traditional classroom learning was not engaging enough, and training outcomes were inconsistent. The company required an interactive digital training solution that could:

- Standardize safety training for all employees

- Minimize training time while improving retention

- Allow realistic practice without real-world risks

- Track individual learning performance

- Improve workplace compliance and reduce accidents

Project Planning:

The project planning phase included:

- Requirement analysis meetings with safety officers and production heads

- Identifying high-risk zones within the factory

- Mapping training objectives with VR modules

- Creating user flow and instruction design

- Selecting hardware – Oculus/HTC VR devices for deployment

- Developing an assessment-based learning structure

The plan focused on creating a multi-level training experience that employees could complete step-by-step, from basic safety orientation to advanced hazard simulation.

Project Process & Execution:

- Content Development

We documented real production floor operations, created safety scripts, and finalized process guidelines. The content covered:

- Electronic component handling

- Machine interaction

- Fire and electrical emergency drills

- PPE compliance

- ESD safety demonstration

- Spill response

- Evacuation procedures

- 3D Environment & Asset Creation

A realistic 3D replica of the client’s manufacturing facility was developed, including:

- Production lines

- SMD machines

- Assembly stations

- Storage racks

- Electrical units

- Safety marking zones

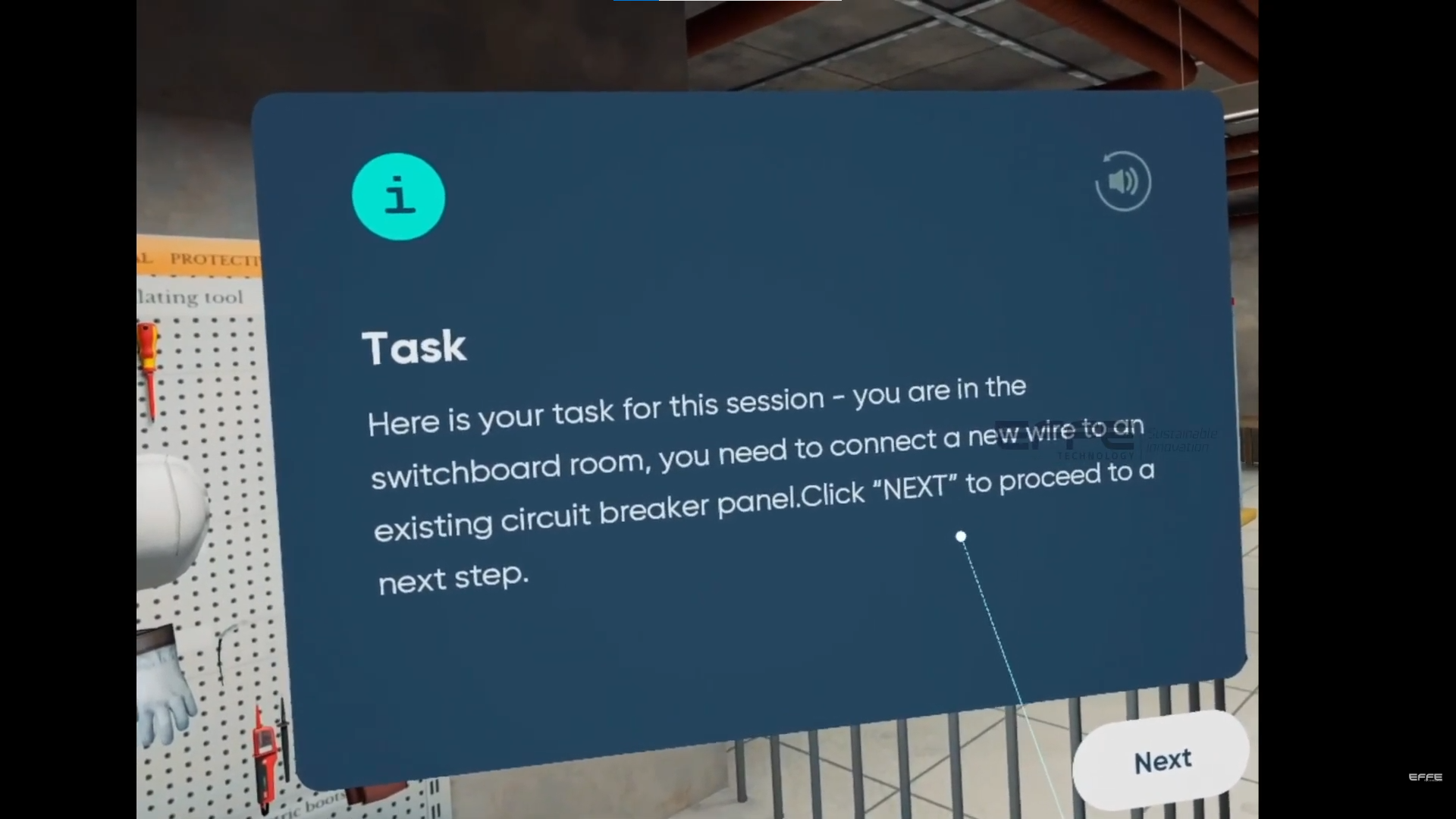

- Interactive VR Simulation

Employees could put on a VR headset and enter a realistic factory environment where they:

- Follow step-by-step guided tasks

- Identify hazards such as exposed circuits, metallic tools near boards, improper PPE use, or fire sources

- Experience real scenarios like short circuits, ESD failures, and equipment malfunction

- Practice correct actions using interactive controllers

- Scoring & Skill Evaluation

Each session included measurable outcomes:

- Time taken

- Errors made

- Correct responses

- Safety compliance percentage

This helped the management evaluate employee readiness before entering the real workspace.

- Multi-language Experience

The training was designed with multi-language support to train workers from diverse backgrounds effectively.

Challenges & Learning:

- Recreating technical workflows accurately required deep production knowledge

- Emergency simulation visuals needed multiple iterations for realism

- Users with no VR experience needed simplified navigation

- Hardware compatibility testing was crucial for smooth deployment

However, the process also delivered key insights:

- VR increased understanding of high-risk safety concepts

- Workers retained information better through immersive learning

- Training became more engaging and measurable

Client Deliverables:

- Full VR safety training application

- Multi-level training modules

- Realistic 3D production environment

- Assessment dashboard and scoring system

- User tutorial and VR navigation guide

- Deployable package for VR headsets

- Documentation and maintenance support

Conclusion:

This project proved that Virtual reality in electronic industry environments can drastically improve safety outcomes by enabling hands-on learning without real risks. The VR safety training for electronics industry solution helped the client reduce training time, improve knowledge retention, standardize skill development, and create a safer workplace.