IoT Digital Twin for Plastic Manufacturing Industry—Optimizing Injection Molding for Quality and Efficiency

Introduction

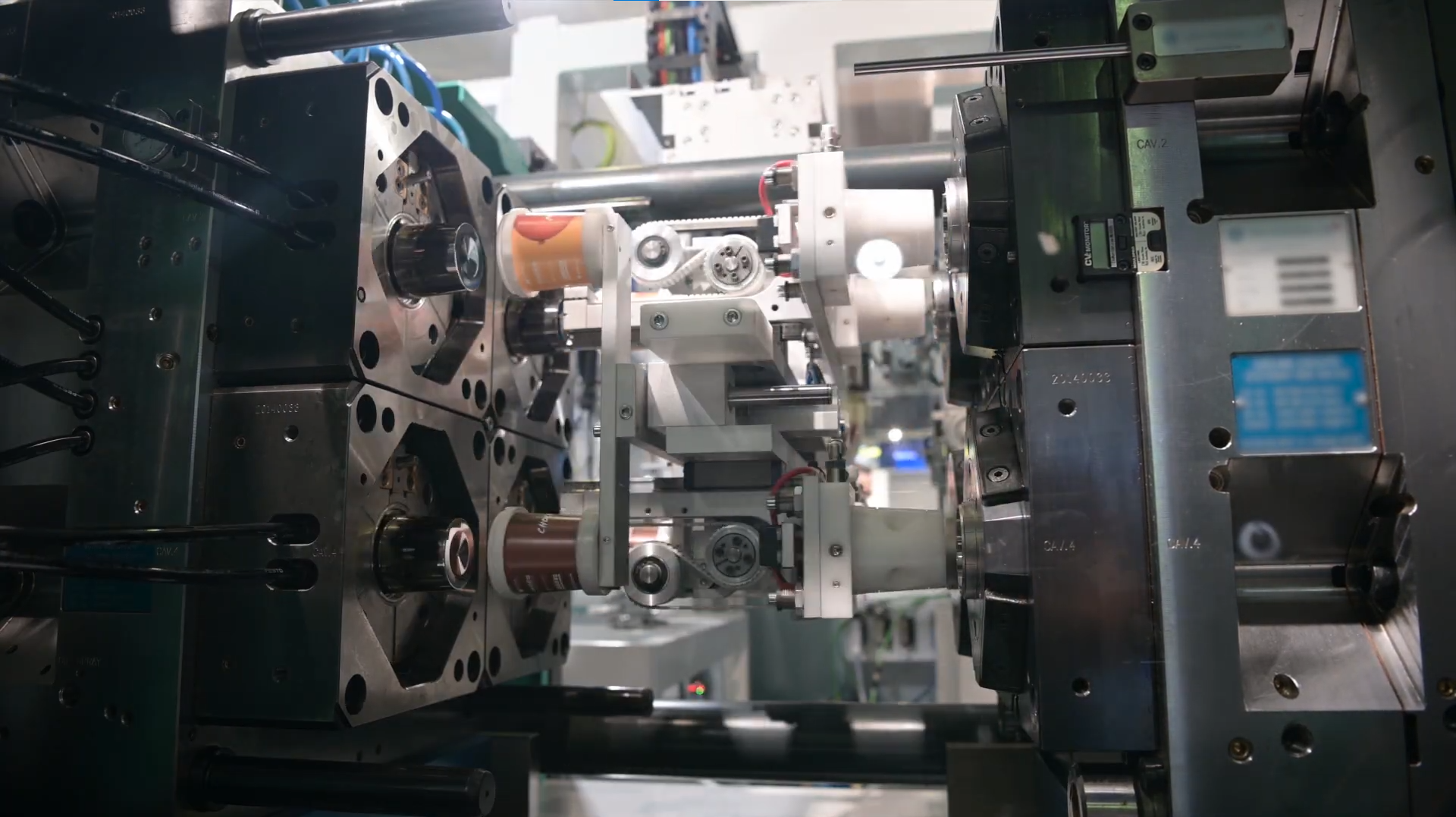

Injection molding is the backbone of plastic part manufacturing, used extensively in the automotive, consumer goods, medical, and packaging industries. Ensuring precision in temperature, pressure, and cycle time is essential for consistent product quality. The integration of the IoT Digital Twin for the plastic manufacturing industry enables manufacturers to simulate, monitor, and control molding operations in real time, reducing defects, improving cycle efficiency, and supporting predictive maintenance.

This case study explores how a mid-size factory enhanced its plastic gear housing production line using IoT-enabled digital twin technology.

Challenges in Plastic Injection Molding

- Frequent quality issues such as warping, sink marks, or short shots.

- Difficulty in monitoring mold cavity temperature, clamping pressure, and resin flow.

- High downtime due to unscheduled maintenance or material inconsistencies.

- Manual inspection processes and lack of traceability for each molded batch.

- Inability to optimize cycle time without risking product defects.

Process of IoT in Injection Molding Automation

- Sensing (Data Collection)

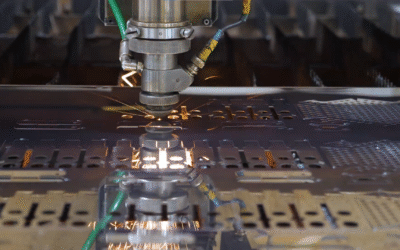

IoT sensors were installed on molds, heaters, pressure valves, injection units, and cooling systems to monitor temperature, pressure, viscosity, flow rate, clamping force, and humidity. This data continuously updated the IoT Digital Twin for Plastic Manufacturing Industry for real-time operational feedback.

- Transmission (Data Transfer)

Data from sensors was transmitted through MQTT/OPC-UA protocols to local edge servers and cloud platforms. This ensured low-latency decision-making and high-volume data storage for analysis.

- Data Processing (Edge or Cloud Computing)

Edge computing managed immediate responses like mold overheating or misalignment. Cloud-based systems processed long-term patterns in material flow behavior and predicted variations caused by ambient temperature shifts.

- Data Storage

All process parameters and sensor data were securely stored by batch and machine ID. This provided an audit trail, enabling better traceability, quality tracking, and compliance.

- Data Analysis (AI/ML Integration)

AI algorithms analyzed variations in shot weight, cycle times, and mold conditions to recommend real-time setting adjustments. ML models predicted when a mold would require cleaning or part replacement to avoid downtime.

- Decision Making / Action Execution

Automated adjustments were made to injection speed, mold temperature, or cooling time. If deviations were detected, alerts were triggered, and machines could be paused or corrected without human intervention.

- User Interface

Operators monitored live dashboards showing mold health, cycle efficiency, real-time part quality metrics, and error trends. Notifications were pushed to maintenance and QA teams for proactive response.

- Digital Twin Interface (Remote Monitoring & Control)

The IoT Digital Twin for Plastic Manufacturing Industry provided a virtual representation of each injection molding machine and mold. Managers could view simulations, test process changes virtually, and monitor operations remotely.

Results and Impact

| Metric | Before Implementation | After Implementation |

| Product Defect Rate (%) | 5.1 | 1.3 |

| Machine Downtime (hours/month) | 14 | 4 |

| Average Cycle Time (seconds) | 38 | 31 |

| Mold Maintenance Frequency (per month) | 3 | 1 |

| Material Waste (kg/month) | 240 | 90 |

- Defect rate reduced by 75% due to better process control and real-time adjustments.

- Cycle time improved by 18%, boosting production capacity.

- Machine uptime increased, thanks to predictive maintenance and fewer unplanned halts.

- Material waste significantly lowered, minimizing cost and environmental impact.

Benefits of IoT Digital Twin for Plastic Manufacturing Industry

- Real-Time Process Control

Ensures consistent mold pressure and temperature, reducing quality issues. - Predictive Maintenance

Anticipates equipment wear and proactively schedules servicing, avoiding costly breakdowns. - Reduced Waste and Rework

Data-driven process optimization leads to better part quality and less scrap. - Improved Traceability

Batch-wise data logging supports audits, certifications, and customer quality requirements. - Remote Monitoring and Simulation

Manufacturing engineers can test parameter changes virtually, saving time during mold setup. - Enhanced Efficiency

Lower cycle times and automated corrections lead to increased throughput and ROI.

Conclusion

The adoption of IoT Digital Twin for Plastic Manufacturing Industry revolutionizes injection molding by transforming it into a smart, adaptive, and data-driven process. With better control over every shot and every machine, manufacturers gain quality, speed, and reliability—leading to more profitable and sustainable operations.

This case study demonstrates how digital twin technology is no longer a future concept but an essential tool for modern plastic production.