IoT Digital Twin for Metal Industry: Streamlining CNC and Laser Cutting Operations

Introduction

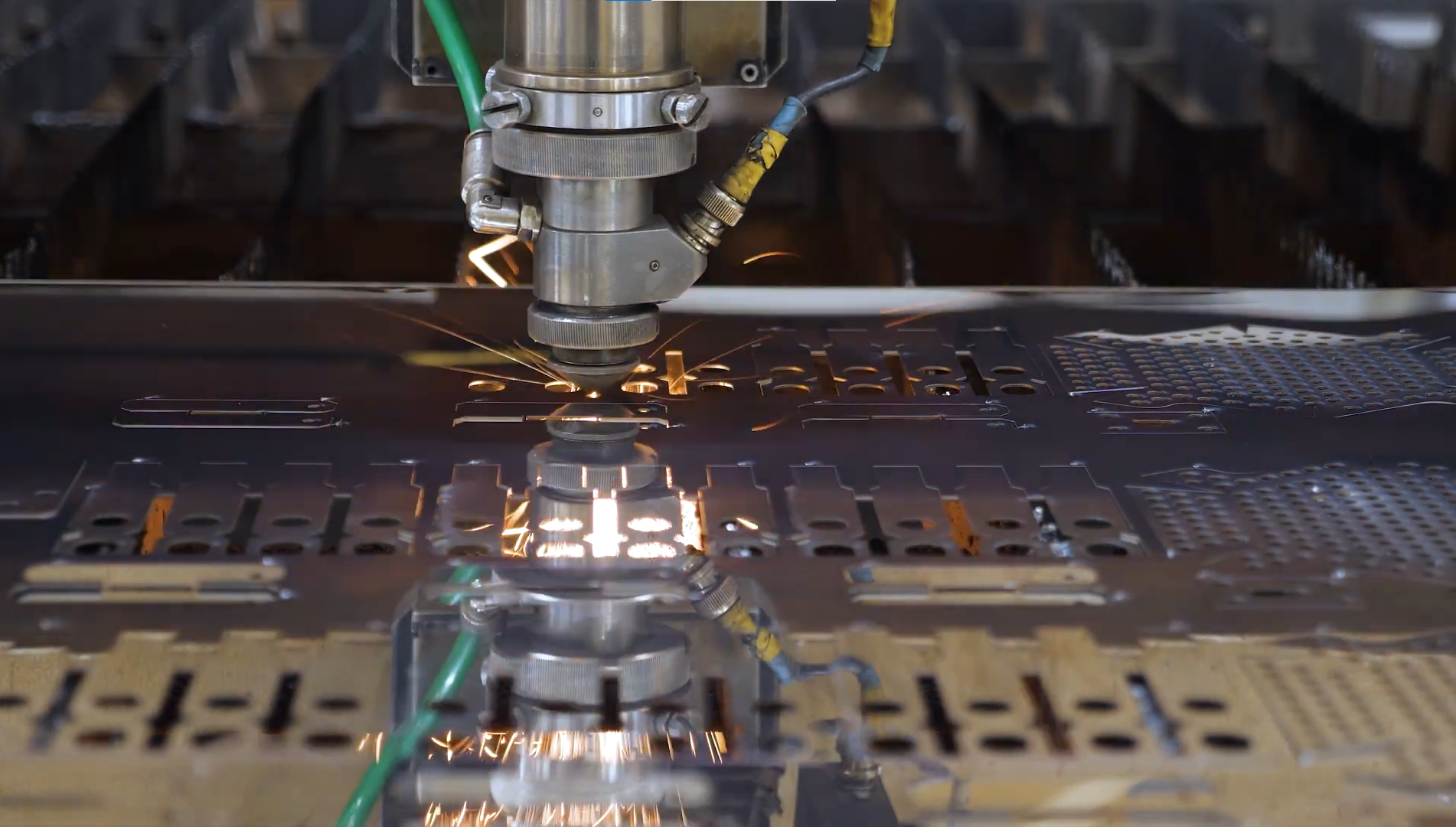

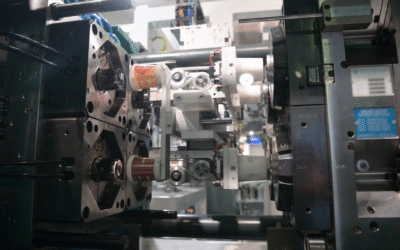

CNC machining, laser cutting, and steel fabrication are precision-intensive processes that demand maximum uptime, tight tolerances, and minimal scrap. However, traditional operations face limitations in predictive maintenance, energy management, and quality assurance. The implementation of the IoT Digital Twin in Metal Industry allows for real-time tracking, simulation, and optimization of critical operations, helping manufacturers achieve superior productivity, lower operational costs, and enhanced consistency.

This case study explores the application of IoT digital twin technology in a CNC and fiber laser cutting workstation used for manufacturing custom structural steel components.

Challenges in Metal Fabrication

- Inconsistent cutting accuracy due to temperature variation and machine wear.

- Tool breakage and unplanned downtime affecting production schedules.

- High material wastage due to cutting errors or manual programming flaws.

- Difficulty in optimizing energy consumption for high-power equipment.

- No real-time visualization of tool health or cut path deviations.

Process of IoT in Metal Fabrication Automation

- Sensing (Data Collection)

IoT sensors were embedded in CNC spindles, servo motors, laser nozzles, and steel plates to collect data such as tool temperature, vibration, feed rate, cutting speed, laser intensity, gas flow, and part alignment. This live data powered the IoT Digital Twin in Metal Industry, offering full visibility into machine health and cutting precision.

- Transmission (Data Transfer)

Data was wirelessly transmitted using MQTT protocols to edge gateways positioned on the shop floor, then securely uploaded to cloud servers for centralized processing and storage.

- Data Processing (Edge or Cloud Computing)

Edge computing units immediately flagged overheating tools or cut deviations, allowing corrective actions. Cloud-based AI systems analyzed historical data to find patterns in wear and optimize toolpath strategies.

- Data Storage

Sensor and performance data were stored in a secure cloud platform, organized by machine, material type, shift, and job ID. This supported future process audits and machining benchmarks.

- Data Analysis (AI/ML Integration)

AI models predicted tool breakage based on vibration signatures and motor loads. ML algorithms optimized cutting speeds, nozzle calibration, and steel sheet layout to minimize waste and energy usage.

- Decision Making/Action Execution

Machines automatically slowed or paused when nearing tool life thresholds. The system recalculated cut paths and adjusted cooling parameters based on real-time heat distribution models.

- User Interface

Operators accessed dashboards showing laser intensity graphs, tool life estimations, and cut quality scores. Alerts were issued for calibration, material misalignment, or potential defects.

- Digital Twin Interface (Remote Monitoring & Control)

The IoT Digital Twin in Metal Industry provided a 3D replica of each machine, visualizing live part machining, spindle performance, and tool paths. Engineers remotely simulated cutting strategies before deployment, improving setup time and reducing trial runs.

Results and Impact

| Metric | Before Implementation | After Implementation |

| Tool Breakage Incidents / Month | 14 | 4 |

| Part Accuracy Deviation (%) | ±3.5% | ±0.8% |

| Scrap Rate per Batch (%) | 6.2 | 1.9 |

| Energy Consumption (kWh/shift) | 1050 | 870 |

| Machine Downtime (hours/month) | 18 | 6 |

- Reduced tool breakage and unplanned downtime by over 65% using predictive analytics.

- Improved cutting precision, reducing rework and increasing client satisfaction.

- Material waste dropped significantly due to intelligent nesting and optimized laser parameters.

- Energy efficiency enhanced, leading to cost savings and sustainability benefits.

Benefits of IoT Digital Twin in Metal Industry

- Predictive Maintenance and Downtime Reduction

Real-time diagnostics and failure prediction help service teams act before breakdowns occur, maintaining production schedules. - Increased Accuracy and Part Quality

Digital twins correct toolpath variations and thermal distortion, leading to highly consistent output with minimal error margin. - Energy Optimization

Smart control of motors, lasers, and compressors reduces unnecessary energy consumption. - Real-Time Simulation and Control

Engineers can simulate cuts virtually, reducing trial-and-error during setup and speeding up cycle time. - Data-Driven Decisions

Production managers use actionable insights to improve machine utilization, throughput, and workforce planning. - Remote Monitoring for Multi-Shift Operations

The digital twin allows supervisors to monitor machines across locations, even after hours or during night shifts.

Conclusion

The IoT Digital Twin in Metal Industry represents a significant step forward in automating and optimizing CNC, laser cutting, and steel fabrication processes. Through real-time monitoring, advanced AI-driven analytics, and virtual replication of physical systems, metalworking facilities can unlock new levels of precision, uptime, and operational control.

This transformation not only improves the bottom line but also ensures that metal fabrication companies stay agile and competitive in a demanding global market. For more content, visit EFFE Technology.